ARG 130 super

We confirm receipt of noncommittal demand

Demanded machine: ARG 130 super

Firstname:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to website

A universal bandsaw is appraised for general use in various workshops (work on locks, maintenance), at plants with machinery and in field installations. Robust framework of the machine is made of grey cast iron. In contrast to the basic version ARG 130, the feed into cut is performed by the weight of the arm with the possibility of regulating the feed rate by a special system of springs. When the cut is finished the bandsaw drive automatically switches off. For fast cutting of small cross-sections the system of springs can be set for manual feed into cut as well. Mechanical lock of the upper position of the bandsaw arm. Arm uplift is carried out manually.

- Modern concept of the bandsaw arm allows for large cutting ranges in upright and angular cuts.

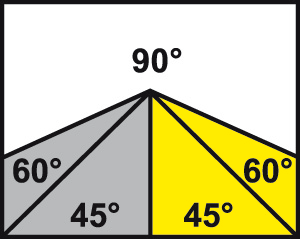

- Continuous adjustment of the cutting angle within the range 90°–60° when the workpiece is clamped tight.

- Simple locking and adjusting of the desired cutting angle on the angle scale.

- Maximum cutting accuracy and saw blade service life in this category of bandsaws.

- High-precision three-side hardmetal bandsaw guidance.

- Manufactured bearing of running wheels, tensioning wheel system and all rotary parts are the same as in big professional machines.

- Professional, noiseless and maintenance-free blade drive is provided by an industrial electric motor with worm gearbox.

- The machine can be equipped with two types of motors. Single-phase motor (230 V) with universal saw blade speed of 75 m/min. facilitates easy mains connection. Three-phase two-speed motor (400 V) with saw blade speed of 40 and 80 m/min. is suitable for frequent cutting of full sections and thick-walled sections.

- The machine is equipped with a 250 mm workpiece stop.

ARG 130 super bandsaws are manufactured in the following versions:

ARG 130 super

Bench bandsaw without cooling.

ARG 130 super TK

Bench bandsaw with cooling. The machine is connected to a complete cooling system with a professional high-performance pump and possibility of regulating the flow on both guiding heads.

ARG 130 super K

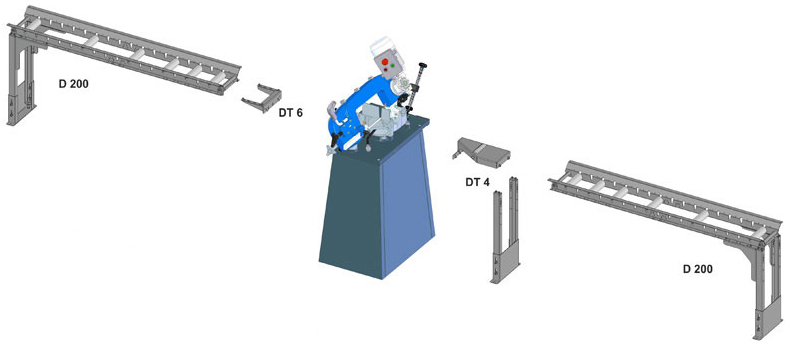

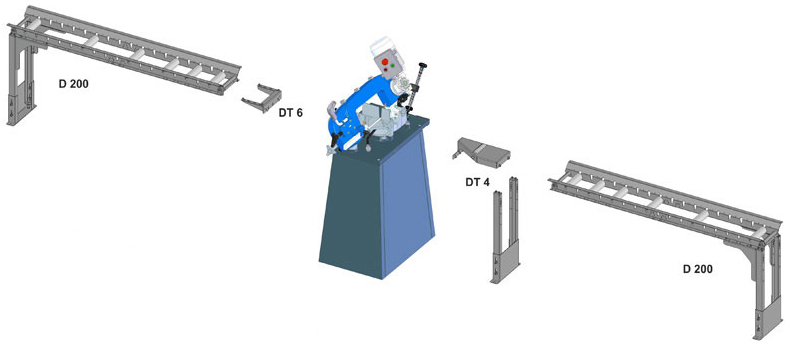

Bandsaw with a base and cooling. The machine is connected to a complete cooling system with a professional high-performance pump and possibility of regulating the flow on both guiding heads. Coolant tank is placed in the base of the machine. This version allows you to install conveyors both before and after the cut.

All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement.

| 90° | +45° | +60° | |

|

130 | 115 | 70 |

|

130 | 105 | 60 |

|

180 x 100 | 115 x 75 | 70 x 60 |

| Main motor | 230 V, 50 Hz, 0,55 kW / 400 V, 50 Hz, 0,37/0,55 kW |

| Pump motor | 230 V, 50 Hz, 0,065 kW / 400 V, 50 Hz, 0,05 kW |

| Saw blade speed | 65 m/min. / 35/65 m/min. |

| Working height vice (with base) | 900 mm |

| Coolant tank | cca 15 l |

| Machine dimensions (min.) | 980 x 420 x 550 mm |

| Machine dimensions (max.) | 1030 x 840 x 1540 mm |

| Machine weight | 70 / 77 / 100 kg |

-

A universal bandsaw is appraised for general use in various workshops (work on locks, maintenance), at plants with machinery and in field installations. Robust framework of the machine is made of grey cast iron. In contrast to the basic version ARG 130, the feed into cut is performed by the weight of the arm with the possibility of regulating the feed rate by a special system of springs. When the cut is finished the bandsaw drive automatically switches off. For fast cutting of small cross-sections the system of springs can be set for manual feed into cut as well. Mechanical lock of the upper position of the bandsaw arm. Arm uplift is carried out manually.

- Modern concept of the bandsaw arm allows for large cutting ranges in upright and angular cuts.

- Continuous adjustment of the cutting angle within the range 90°–60° when the workpiece is clamped tight.

- Simple locking and adjusting of the desired cutting angle on the angle scale.

- Maximum cutting accuracy and saw blade service life in this category of bandsaws.

- High-precision three-side hardmetal bandsaw guidance.

- Manufactured bearing of running wheels, tensioning wheel system and all rotary parts are the same as in big professional machines.

- Professional, noiseless and maintenance-free blade drive is provided by an industrial electric motor with worm gearbox.

- The machine can be equipped with two types of motors. Single-phase motor (230 V) with universal saw blade speed of 75 m/min. facilitates easy mains connection. Three-phase two-speed motor (400 V) with saw blade speed of 40 and 80 m/min. is suitable for frequent cutting of full sections and thick-walled sections.

- The machine is equipped with a 250 mm workpiece stop.

ARG 130 super bandsaws are manufactured in the following versions:

ARG 130 superBench bandsaw without cooling.

ARG 130 super TKBench bandsaw with cooling. The machine is connected to a complete cooling system with a professional high-performance pump and possibility of regulating the flow on both guiding heads.

ARG 130 super KBandsaw with a base and cooling. The machine is connected to a complete cooling system with a professional high-performance pump and possibility of regulating the flow on both guiding heads. Coolant tank is placed in the base of the machine. This version allows you to install conveyors both before and after the cut.

All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement.

-

90° +45° +60°

130 115 70

130 105 60

180 x 100 115 x 75 70 x 60 Main motor 230 V, 50 Hz, 0,55 kW / 400 V, 50 Hz, 0,37/0,55 kW Pump motor 230 V, 50 Hz, 0,065 kW / 400 V, 50 Hz, 0,05 kW Saw blade speed 65 m/min. / 35/65 m/min. Working height vice (with base) 900 mm Coolant tank cca 15 l Machine dimensions (min.) 980 x 420 x 550 mm Machine dimensions (max.) 1030 x 840 x 1540 mm Machine weight 70 / 77 / 100 kg -

-