ARG 640 DC S.A.F.

Confirmamos la recepción de la consulta no vinculante

Máquina de interés: ARG 640 DC S.A.F.

Empresa:

Kontaktní osoba:

IČO:

Adresa:

Teléfono:

E-mail:

Su pregunta:

Región de destino:

Tan pronto sea posible nos pondremos en contacto con los datos que ha ingresado.

Volver a la página

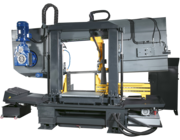

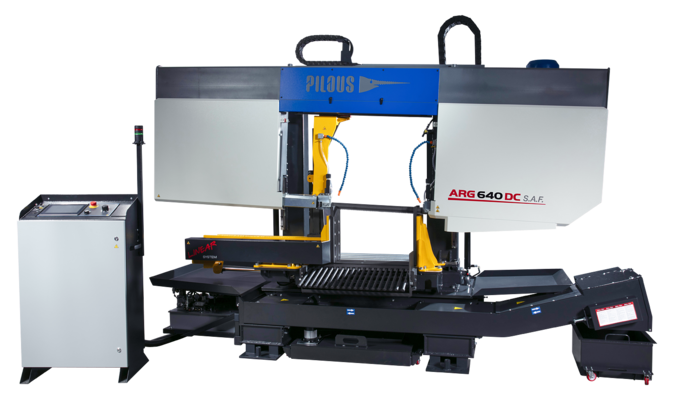

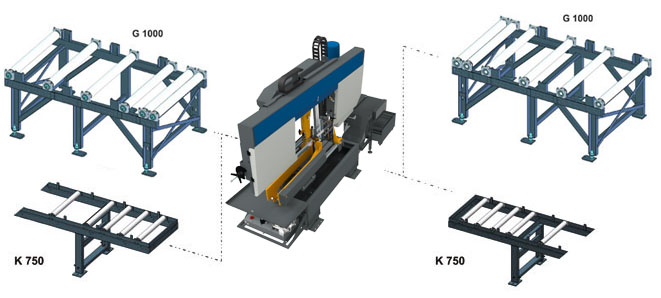

Massive double-column semi-automatic machine designed for versatile use in the industrial cutting of materials even in the most challenging and non-stop applications and also for cutting heavy workpieces of larger cross-sections. Exceptionally solid construction of the saw band arm and the massive dual-column arm support moving on linear lines ensure excellent stiffness of the whole system and accurate cut during industrial cutting of full materials. Industrial band 54 x 1.6 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel.

Optimum clamping of the workpiece when cutting is facilitated by full-stroke vice. Pressing a single switch will execute complete cutting cycle - material clamping, band and cooling system start, cutting, band and cooling stop, arm uplift to the original adjustable position and vice unclamping. When you switch to the manual mode you can control all functions separately.

Easy intuitive controls through a touchscreen on an ergonomic central control panel. The display also shows required lifting height of the saw band arm depending on the cross section of the material to be cut. Moreover it allows you to monitor the number of cut workpieces in the current settings and machine diagnostics (PLC inputs and outputs, history of errors). During cutting the display shows saw band speed, speed of the arm feeding, main engine load and any potential error messages.

The machine is equipped with a high-performance industrial hydraulic unit which allows setting of the contact pressure of the vice. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band speed by a frequency converter in the range between 15 and 90 m/min., which significantly contributes to cutting accuracy and service life of saw bands. Large base and overall massive framework guarantee exceptional stability of the machine even when cutting heavy workpieces. By default the machine is equipped with a solid screw chip conveyor. Its location right below the cut ensures optimum removal of chips. High-quality lighting of the work area by a line of powerful LEDs with a cover.

- In order to achieve maximum accuracy and productivity the machine is designed only for perpendicular cutting.

- Very robust machine construction composes of massive weldments ensures vibration absorption.

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with bevel gearbox.

- The machine is connected to a complete cooling system with the possibility of regulating the flow on both guiding heads independently and ontwo additional adjustable outlets. The coolant tank with a high-performance pump are placed in the base of the machine.

- The machine checks correct tension or break of the saw band. If the saw band breaks the machine automatically switches off.

All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement.

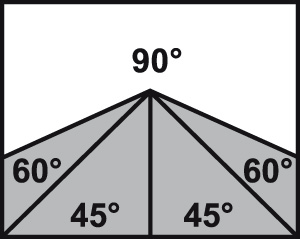

| 90° | |

|

640 |

|

600 |

|

800 x 550 |

| Main motor | 400 V, 50 Hz, 7.5 kW |

| Pump motor | 400 V, 50 Hz, 0.12 kW |

| Hydraulic motor unit | 400 V, 50 Hz, 1.5 kW |

| Saw blade speed | 15-90 m/min. |

| Working height of vice | 807 mm |

| Hydraulic system oil | approx. 45 l (ISO 6743/4-HM, DIN 51 524 part 2-HLP) |

| Coolant tank | approx. 70 l |

| Machine dimensions | Dimension drawing |

| Machine weight | 3000 kg |

-

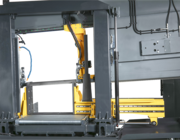

Dispositivo de presión hidráulica HVP

El dispositivo de presión de carrera completa asegura una sujeción vertical óptima al cortar materiales en paquetes. La placa de presión controlada hidráulicamente con altura de elevación ajustable se guía sobre guías lineales y sujeta el material a lo largo de toda la longitud del tornillo de banco. La altura de elevación, según el tamaño del material a cortar, se ajusta fácilmente en la pantalla táctil y la sujeción está sincronizada con el tornillo de banco vertical.

-

Baliza de señalización M2

Sirve para el control visual remoto del estado de funcionamiento de la máquina. La baliza de dos colores está equipada con luces LED de alta luminosidad y visibilidad desde todas las direcciones gracias a la forma única de las lentes.

Luz verde: señaliza el modo de trabajo de la máquina, la cinta de sierra está en corte. Al finalizar el corte y detener la cinta de sierra, la luz se apaga y le indica que puede iniciar el siguiente corte.

Luz roja: señaliza una avería, por ejemplo, una cinta de sierra rota, sobrecarga del motor principal, cubierta de seguridad abierta y otros fallos que llevan a la parada de la máquina.

-

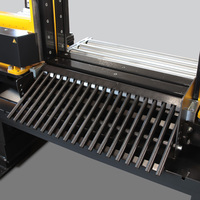

Transportador de virutas tipo rastrillo SDA

Asegura la eliminación continua de virutas fuera de la máquina. Esto reduce el tiempo necesario para limpiar la máquina, especialmente durante el corte en serie de materiales sólidos, donde se genera una gran cantidad de virutas. Ideal para virutas pequeñas y quebradizas y virutas de hierro fundido.

-

Transportador de virutas de cadena SDC

El transportador de virutas de cadena está equipado con una cinta transportadora de acero sobre la cual caen las virutas y son transportadas a un contenedor de recolección preparado mediante transportadores transversales. Esta cinta de cadena completa con salientes evita que las virutas se adhieran a la cinta. Las placas completas de la cinta evitan que las virutas pequeñas pasen a través de la cinta. Este tipo también es adecuado para virutas de aluminio.

-

Massive double-column semi-automatic machine designed for versatile use in the industrial cutting of materials even in the most challenging and non-stop applications and also for cutting heavy workpieces of larger cross-sections. Exceptionally solid construction of the saw band arm and the massive dual-column arm support moving on linear lines ensure excellent stiffness of the whole system and accurate cut during industrial cutting of full materials. Industrial band 54 x 1.6 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel.

Optimum clamping of the workpiece when cutting is facilitated by full-stroke vice. Pressing a single switch will execute complete cutting cycle - material clamping, band and cooling system start, cutting, band and cooling stop, arm uplift to the original adjustable position and vice unclamping. When you switch to the manual mode you can control all functions separately.

Easy intuitive controls through a touchscreen on an ergonomic central control panel. The display also shows required lifting height of the saw band arm depending on the cross section of the material to be cut. Moreover it allows you to monitor the number of cut workpieces in the current settings and machine diagnostics (PLC inputs and outputs, history of errors). During cutting the display shows saw band speed, speed of the arm feeding, main engine load and any potential error messages.

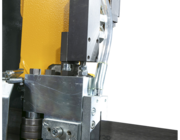

The machine is equipped with a high-performance industrial hydraulic unit which allows setting of the contact pressure of the vice. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band speed by a frequency converter in the range between 15 and 90 m/min., which significantly contributes to cutting accuracy and service life of saw bands. Large base and overall massive framework guarantee exceptional stability of the machine even when cutting heavy workpieces. By default the machine is equipped with a solid screw chip conveyor. Its location right below the cut ensures optimum removal of chips. High-quality lighting of the work area by a line of powerful LEDs with a cover.

- In order to achieve maximum accuracy and productivity the machine is designed only for perpendicular cutting.

- Very robust machine construction composes of massive weldments ensures vibration absorption.

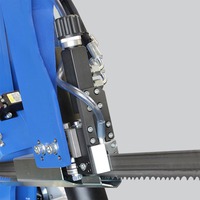

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with bevel gearbox.

- The machine is connected to a complete cooling system with the possibility of regulating the flow on both guiding heads independently and ontwo additional adjustable outlets. The coolant tank with a high-performance pump are placed in the base of the machine.

- The machine checks correct tension or break of the saw band. If the saw band breaks the machine automatically switches off.

All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement.

-

90°

640

600

800 x 550 Main motor 400 V, 50 Hz, 7.5 kW Pump motor 400 V, 50 Hz, 0.12 kW Hydraulic motor unit 400 V, 50 Hz, 1.5 kW Saw blade speed 15-90 m/min. Working height of vice 807 mm Hydraulic system oil approx. 45 l (ISO 6743/4-HM, DIN 51 524 part 2-HLP) Coolant tank approx. 70 l Machine dimensions Dimension drawing Machine weight 3000 kg -

-

-

Dispositivo de presión hidráulica HVP

El dispositivo de presión de carrera completa asegura una sujeción vertical óptima al cortar materiales en paquetes. La placa de presión controlada hidráulicamente con altura de elevación ajustable se guía sobre guías lineales y sujeta el material a lo largo de toda la longitud del tornillo de banco. La altura de elevación, según el tamaño del material a cortar, se ajusta fácilmente en la pantalla táctil y la sujeción está sincronizada con el tornillo de banco vertical.

-

Baliza de señalización M2

Sirve para el control visual remoto del estado de funcionamiento de la máquina. La baliza de dos colores está equipada con luces LED de alta luminosidad y visibilidad desde todas las direcciones gracias a la forma única de las lentes.

Luz verde: señaliza el modo de trabajo de la máquina, la cinta de sierra está en corte. Al finalizar el corte y detener la cinta de sierra, la luz se apaga y le indica que puede iniciar el siguiente corte.

Luz roja: señaliza una avería, por ejemplo, una cinta de sierra rota, sobrecarga del motor principal, cubierta de seguridad abierta y otros fallos que llevan a la parada de la máquina.

-

Transportador de virutas tipo rastrillo SDA

Asegura la eliminación continua de virutas fuera de la máquina. Esto reduce el tiempo necesario para limpiar la máquina, especialmente durante el corte en serie de materiales sólidos, donde se genera una gran cantidad de virutas. Ideal para virutas pequeñas y quebradizas y virutas de hierro fundido.

-

Transportador de virutas de cadena SDC

El transportador de virutas de cadena está equipado con una cinta transportadora de acero sobre la cual caen las virutas y son transportadas a un contenedor de recolección preparado mediante transportadores transversales. Esta cinta de cadena completa con salientes evita que las virutas se adhieran a la cinta. Las placas completas de la cinta evitan que las virutas pequeñas pasen a través de la cinta. Este tipo también es adecuado para virutas de aluminio.