- SIERRAS DE CINTA PARA METAL

- MÁQUINAS DE DESBARBADO

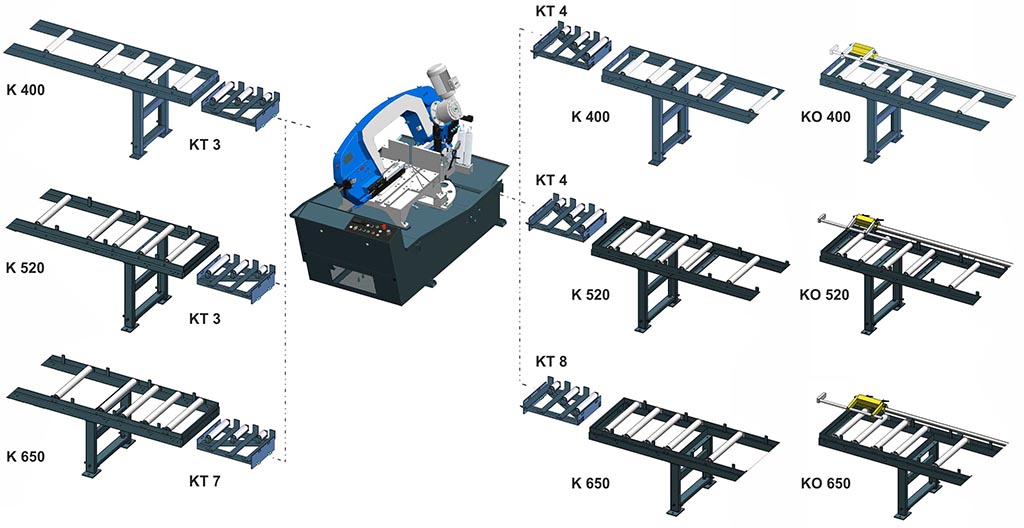

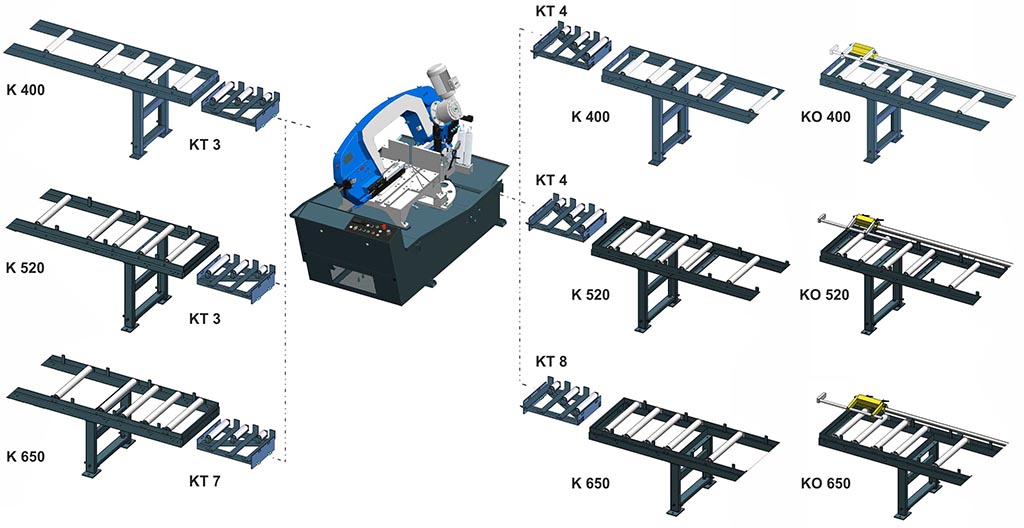

- TRANSPORTADORES DE RODILLOS

- HOJAS DE SIERRA

- EMULSIONES

ARG 400 plus S.A.F.

Confirmamos la recepción de la consulta no vinculante

Máquina de interés: ARG 400 plus S.A.F.

Empresa:

Kontaktní osoba:

IČO:

Adresa:

Teléfono:

E-mail:

Su pregunta:

Región de destino:

Tan pronto sea posible nos pondremos en contacto con los datos que ha ingresado.

Volver a la página

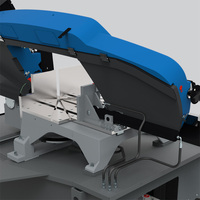

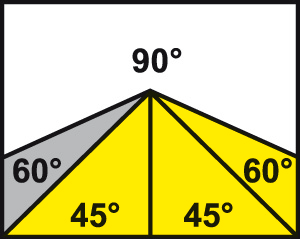

Exceptionally robust construction of the whole machine. Band saw arm made of grey cast iron in this size of band saws is completely exceptional. It ensures high cutting accuracy and long service life of the machine. Complete massive construction of the machine is designed primarily for industrial cutting of full materials even in the most difficult conditions. Thanks to the range of cutting angles of 60° to the right and 45° to the left the band saw is suitable for universal use in all production plants. The saw band sized 34 x 1.1 mm ensures accurate cutting of large cross-sections. The band is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel.

Easy intuitive controls through a touchscreen on a central control panel. The display also shows required lifting height of the saw band arm depending on the cross section of the material to be cut. Moreover it allows you to monitor the number of cut workpieces in the current settings and machine diagnostics (PLC inputs and outputs, history of errors). During cutting the display shows saw band speed, main engine load and any potential error messages. The display also shows cutting angle settings. Special accessories.

When you switch to the manual mode you can control all functions separately. The machine is equipped with a high-performance industrial hydraulic unit which allows setting of the contact pressure of the vice. All of this in connection with hydraulics-controlled saw band feed into cut significantly increases cutting efficiency, especially in larger series and cutting of full and high-quality materials. Pressing a single switch will execute complete cutting cycle – material clamping, band and cooling system start, cutting, band and cooling stop, arm uplift to the original adjustable position and vice unclamping. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band rate by a frequency converter in the range between 15 and 90 m/min., which significantly contributes to cutting accuracy and service life of saw bands.

- In order to achieve maximum stiffness of the whole system and cutting accuracy, the band saw arm is attached to a sturdy grey cast iron turntable on both sides in massive “houses” fitted with pre-stressing tapered roller bearings.

- Massive machine base and exceptionally robust grey cast iron vice with a large material loading surface. The base of the machine is by default equipped with a removable chips container or with an additional chips conveyor.

- The system is mounted on tapered roller bearings in order to facilitate the easiest possible rotation of the arm during angular cutting.

- Simple locking and adjusting of a required cutting angle on the angle scale or, as additional accessories, digital monitoring on a touch screen.

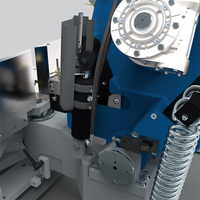

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an in-dustrial electric motor with worm gearbox.

- The machine is connected to a complete cooling system with a high-performance pump and possibility of regulating the flow on both guiding heads independently and on an additional adjustable outlet. Coolant tank with a pump is placed in the base of the machine.

- The machine checks correct tension or break of the saw band. If the saw band breaks the machine automatically switches off.

- Easy control by ergonomically placed controls (electrical and hydraulics) on the base of the machine.

- The touch screen, PLC, and frequency inverter are provided by Schneider Electric.

| 90° | -45° | +45° | +60° | |

|

400 | 290 | 300 | 200 |

|

400 | 250 | 300 | 200 |

|

460 x 300 | 300 x 170 | 300 x 200 | 200 x 200 |

| Main motor | 400 V, 50 Hz, 3 kW |

| Pump motor | 400 V, 50 Hz, 0,12 kW |

| Hydraulic motor unit | 400 V, 50 Hz, 0,55 kW |

| Saw blade speed | 15-90 m/min. |

| Working height of vice | 795 mm |

| Hydraulic system oil | cca 26 l (ISO 6743/4-HM, DIN 51 524 část 2-HLP) |

| Coolant tank | cca 35 l |

| Machine dimensions | Dimension drawing |

| Machine weight | 1225 kg |

-

Bandeja de acero inoxidable y separador de virutas

La robusta bandeja de acero inoxidable es un complemento opcional que permite equipar la máquina con un separador de virutas. El separador de virutas es un recipiente galvanizado y finamente perforado que sirve para la recolección eficiente de las virutas que pasan por el tamiz en la base. Este recipiente es fácilmente extraíble y se puede limpiar fácilmente fuera de la máquina.

-

Bandeja de acero inoxidable y separador magnético de virutas

La robusta bandeja de acero inoxidable es un complemento opcional que permite equipar la máquina con un separador magnético de virutas. Para virutas especialmente finas que pasan por los tamices en la sierra, se utiliza un separador magnético altamente eficiente. Ahorra tiempo de limpieza y desmontaje del sistema de refrigeración y prolonga la vida útil del refrigerante. Este dispositivo es fácilmente extraíble y se puede limpiar fácilmente fuera de la máquina simplemente retirando las barras magnéticas de la carcasa.

-

Exceptionally robust construction of the whole machine. Band saw arm made of grey cast iron in this size of band saws is completely exceptional. It ensures high cutting accuracy and long service life of the machine. Complete massive construction of the machine is designed primarily for industrial cutting of full materials even in the most difficult conditions. Thanks to the range of cutting angles of 60° to the right and 45° to the left the band saw is suitable for universal use in all production plants. The saw band sized 34 x 1.1 mm ensures accurate cutting of large cross-sections. The band is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel.

Easy intuitive controls through a touchscreen on a central control panel. The display also shows required lifting height of the saw band arm depending on the cross section of the material to be cut. Moreover it allows you to monitor the number of cut workpieces in the current settings and machine diagnostics (PLC inputs and outputs, history of errors). During cutting the display shows saw band speed, main engine load and any potential error messages. The display also shows cutting angle settings. Special accessories.

When you switch to the manual mode you can control all functions separately. The machine is equipped with a high-performance industrial hydraulic unit which allows setting of the contact pressure of the vice. All of this in connection with hydraulics-controlled saw band feed into cut significantly increases cutting efficiency, especially in larger series and cutting of full and high-quality materials. Pressing a single switch will execute complete cutting cycle – material clamping, band and cooling system start, cutting, band and cooling stop, arm uplift to the original adjustable position and vice unclamping. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band rate by a frequency converter in the range between 15 and 90 m/min., which significantly contributes to cutting accuracy and service life of saw bands.

- In order to achieve maximum stiffness of the whole system and cutting accuracy, the band saw arm is attached to a sturdy grey cast iron turntable on both sides in massive “houses” fitted with pre-stressing tapered roller bearings.

- Massive machine base and exceptionally robust grey cast iron vice with a large material loading surface. The base of the machine is by default equipped with a removable chips container or with an additional chips conveyor.

- The system is mounted on tapered roller bearings in order to facilitate the easiest possible rotation of the arm during angular cutting.

- Simple locking and adjusting of a required cutting angle on the angle scale or, as additional accessories, digital monitoring on a touch screen.

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an in-dustrial electric motor with worm gearbox.

- The machine is connected to a complete cooling system with a high-performance pump and possibility of regulating the flow on both guiding heads independently and on an additional adjustable outlet. Coolant tank with a pump is placed in the base of the machine.

- The machine checks correct tension or break of the saw band. If the saw band breaks the machine automatically switches off.

- Easy control by ergonomically placed controls (electrical and hydraulics) on the base of the machine.

- The touch screen, PLC, and frequency inverter are provided by Schneider Electric.

-

90° -45° +45° +60°

400 290 300 200

400 250 300 200

460 x 300 300 x 170 300 x 200 200 x 200 Main motor 400 V, 50 Hz, 3 kW Pump motor 400 V, 50 Hz, 0,12 kW Hydraulic motor unit 400 V, 50 Hz, 0,55 kW Saw blade speed 15-90 m/min. Working height of vice 795 mm Hydraulic system oil cca 26 l (ISO 6743/4-HM, DIN 51 524 část 2-HLP) Coolant tank cca 35 l Machine dimensions Dimension drawing Machine weight 1225 kg -

-

-

Bandeja de acero inoxidable y separador de virutas

La robusta bandeja de acero inoxidable es un complemento opcional que permite equipar la máquina con un separador de virutas. El separador de virutas es un recipiente galvanizado y finamente perforado que sirve para la recolección eficiente de las virutas que pasan por el tamiz en la base. Este recipiente es fácilmente extraíble y se puede limpiar fácilmente fuera de la máquina.

-

Bandeja de acero inoxidable y separador magnético de virutas

La robusta bandeja de acero inoxidable es un complemento opcional que permite equipar la máquina con un separador magnético de virutas. Para virutas especialmente finas que pasan por los tamices en la sierra, se utiliza un separador magnético altamente eficiente. Ahorra tiempo de limpieza y desmontaje del sistema de refrigeración y prolonga la vida útil del refrigerante. Este dispositivo es fácilmente extraíble y se puede limpiar fácilmente fuera de la máquina simplemente retirando las barras magnéticas de la carcasa.

-