What is blade run-in? Why is it important?

We commonly encounter customer requests such as: “Could you please sell me exactly the same saw blade that was installed when the machine was purchased? That one lasted the longest for us!” The reason that particular blade lasted the longest is that it was used for the final test of the Pilous band saw, and our technicians perform that test with the utmost care at a low downfeed speed into the cut and at a low blade speed. As a result, the blade is well run-in.

What happens to the saw blade during run-in

Run-in of a bimetal saw blade is essential because a new blade has extremely sharp and brittle tooth tips that must be gradually rounded off to prevent chipping and a significant reduction in service life. Proper run-in extends blade life and improves cut quality. Run-in is a controlled initial operation of a new saw blade during which the sharp edges of the teeth are shaped into an optimal form and the blade material “settles” on the saw. New teeth are manufactured very sharp and microscopic tips are prone to breakage if the blade is immediately loaded at full power. Therefore, the aim of run-in is to reduce mechanical and thermo‑mechanical shocks and to create a stable cutting geometry.

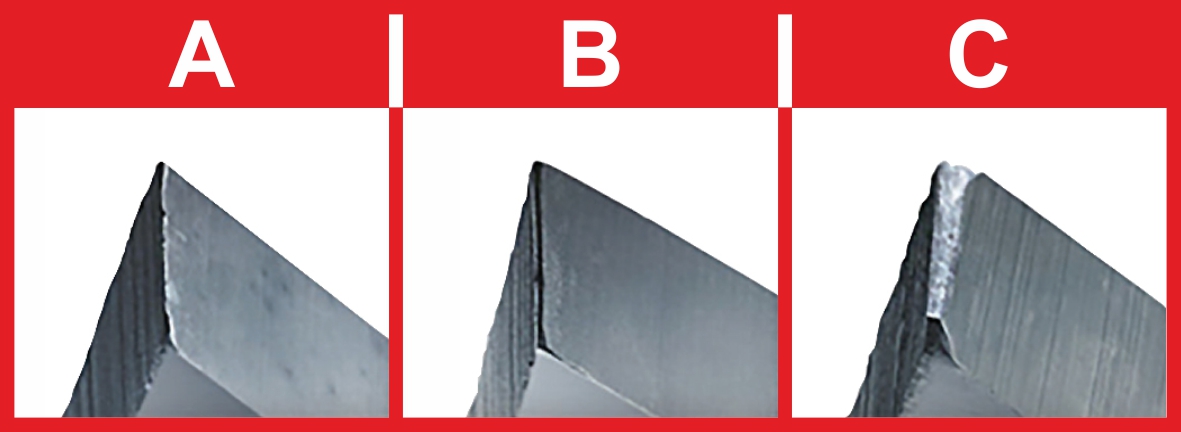

A - new tooth • B - properly run-in tooth • C - poorly run-in tooth

Photo source: Wikus

Why it is really worthwhile

The main benefits of a correct run-in are a significant extension of blade life, improved flatness and cut quality, and a reduced risk of premature tooth damage. Practical experience shows that a properly run-in blade can last tens of percent longer and maintain stable cutting properties, whereas immediate use at full power often leads to premature dulling of the blade, breakage of tooth tips, crooked cuts and, if such a blade is left on the machine, even to the blade breaking.

How to run in correctly

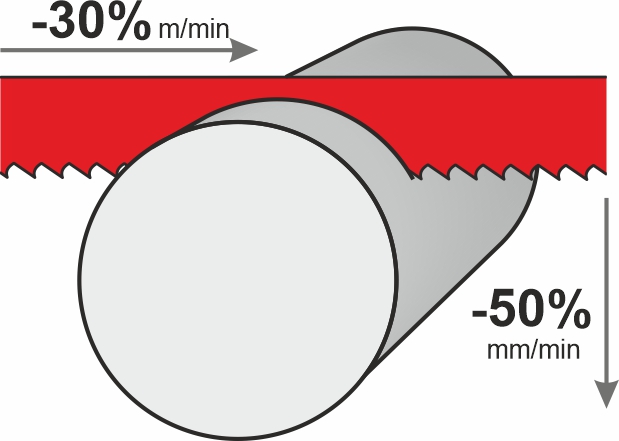

There are several proven procedures that vary by manufacturer and material type, but the common principles are the same: reduce cutting speed and feed, ensure continuous chip formation, and gradually increase the load. Pilous recommends reducing the blade speed by 30% of the recommended speed for the given material and reducing the downfeed speed into the cut to approximately 50% of the recommended downfeed speed for low‑carbon steels. For tough materials, we recommend reducing the downfeed speed by up to 75% of the recommended downfeed speed. Start with the first cut and make sure the teeth are producing chips. Once the blade is fully engaged in the workpiece, the blade speed and downfeed speed can be slightly adjusted to eliminate vibration or squealing. For small cross‑sections of the material being cut, run-in at reduced power for approximately 15 minutes is recommended; for larger cross‑sections, approximately 30 minutes. Then slowly increase the feed to the optimal value.

During run-in, it is crucial to monitor chip formation — the chips must be fine and continuous, and the blade must not “grind” the surface without producing chips. It is also advisable to start the machine daily at lower power to avoid thermal shock to the blade. Regular inspection of the blade guides, blade condition, and cooling system significantly reduces the risk of failures and premature blade wear.

Summary

Run-in is not a waste of time but an investment in operational reliability and economy. Proper run-in increases blade life, improves cut quality and reduces operating costs. Following the recommended procedures — reducing speed and pressure, ensuring chip formation, gradually increasing load and careful maintenance — will yield measurable savings and fewer production stoppages.