Bandsaw blades

- Original bandsaw blades produced using the latest technology with top-quality German materials, while strictly complying with all stated production and control procedures.

- High productivity and precision of cut with the maximum service life of the blade is ensured.

- Wide range of produced types of sawblades and toothing enables the professional cutting of almost all available materials.

|

|

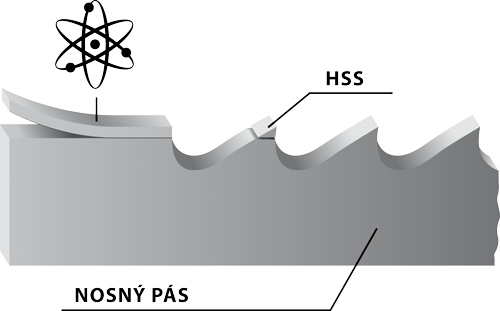

Consists of bearing band from special steel on which a layer of HSS material is welded into where the teeth are milled. |

|

|

Constant toothingThe distance of the teeth are always the same. |

|

|

Variable toothingThe distance of teeth vary and is periodically repeated. This results in a greater cutting range, ability to further eliminate vibrations caused by the impact of the tooth blade on material, longer service life of the blade. |

M42

Universal blade recommended for a wide palette of material, including tool steels and stainless steel up to hardness 45 HRC. Teeth are made from steel HSS-M42 containing cobalt.

M51

Blade for tool and stainless steel with hardness up to 50 HRC. Tooth tips are made from steel HSS-M42 containing cobalt and wolfram

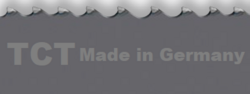

Carbide

Consists of bearing band from special steel into which the teeth are milled on which especially grinded carbide plates are welded. The carbide mounted blade is recommended for cutting surface hardened materials, chrome parts, forged pieces and materials with external tenacity and hardness up to 62 HRC.

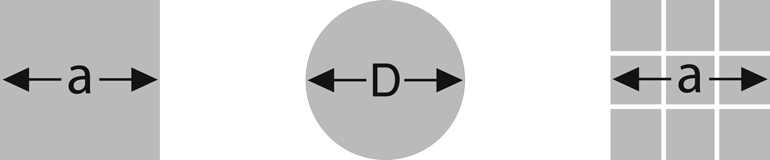

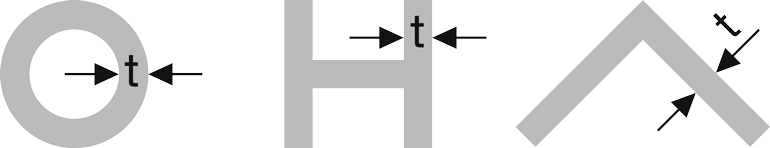

Cutting range

For optimal output of the blade, the correct selection of the size of the blade tooth is important depending on the size of the divided material.

| SOLID MATERIALS | PROFILED MATERIALS |

|---|---|

|

|

| Variable toothing | Constant toothing | Variable toothing | Constant toothing | ||||

|---|---|---|---|---|---|---|---|

| a(D) [mm] |  |

a(D) [mm] |  |

t [mm] |  |

t [mm] |  |

| 0–25 | 10/14 | 0-10 | 18 | 0-4 | 10/14 | 0-1 | 18 |

| 20-40 | 8/12 (8/11) | 5-20 | 14 | 3-6 | 8/12 (8/11) | 0-3 | 14 |

| 30-60 | 6/10 | 20-40 | 10 | 6-9 | 6/10 | 4-7 | 10 |

| 40-70 | 5/8 (5/7) | 40-80 | 6 | 9-13 | 5/8 (5/7) | 8-11 | 6 |

| 60-110 | 4/6 | 80-120 | 4 | 12-16 | 4/6 | 12-15 | 4 |

| 80-140 | 3/4 | 120-200 | 3 | 16-22 | 3/4 | 16-20 | 3 |

| 120-350 | 2/3 | 200-400 | 2 | 20-35 | 2/3 | 21-30 | 2 |

| 250-550 | 1,4-2 | 300-800 | 1,25 | 30-85 | 1,4-2 | 31-90 | 1,25 |

| 380-750 | 1/1,5 | 40-85 | 1/1,5 | ||||

| 550-3000 | 0,75/1,25 | 80-200 | 0,75-1,25 | ||||

When selecting the number of teeth for the blade, the general principle applies of a minimum of 4 teeth, but no more than 30 teeth are in contact with the work piece.

|

Be careful when unpacking welded saw blades. They are in a shipping container in tensioned condition. Remove the saw blade cover only after fitting it onto the machine. |