When to choose a single‑pivot (hinged) band saw and when a double-column band saw

Band saws have long been among the best‑selling machines for cutting metal materials, mainly because they allow large material cross‑sections to be cut, the machines are relatively affordable, tooling costs are low, and their energy consumption is modest. By contrast, circular saws, for example, provide a cleaner and faster cut.

Despite the seemingly simple principle of a continuous blade, the design of a modern band saw is the result of a complex engineering process that must respect the physical limits of the saw blade itself. A saw blade is a tool with very sharp but also brittle teeth. Excessive vibration, in particular, can cause teeth to break off or even destroy the entire blade. For this reason, the saw’s design is always to a large extent subordinated to the requirement of minimizing vibration during the cutting process.

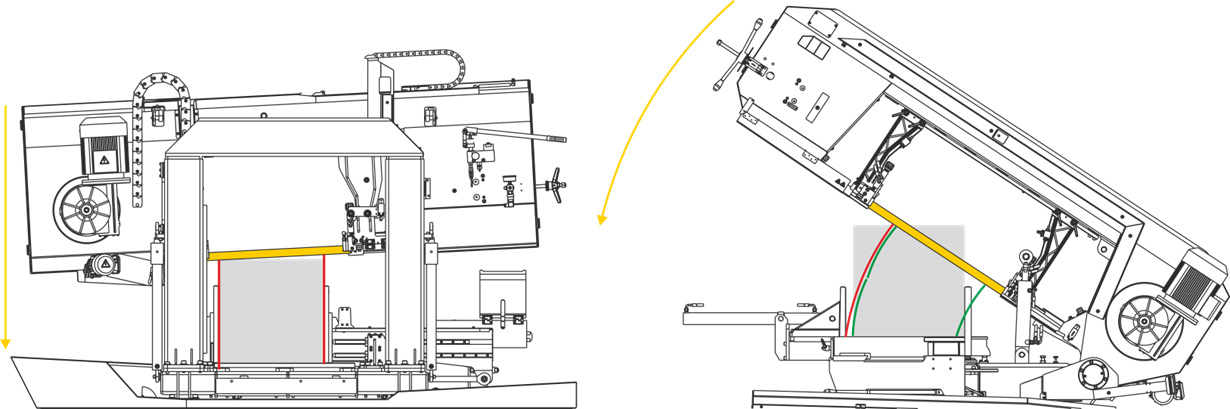

In this context, two main design platforms differ fundamentally: hinged (single‑pivot) band saws, where the arm moves along a circular path around a single pivot, and double-column band saws, whose arm is guided linearly along a pair of parallel columns. These structural differences significantly affect stability, accuracy, and cutting speed. The following text examines in detail the mechanical principles of both systems, the reasons for differences in cutting speed for solid and profile materials, the impact of vibrations on tool life, and the overall optimization of the cutting process.

Pivot (hinged) band saws and their design characteristics

Pivot (hinged) band saws use an arm mounted on a single rotating pivot. During cutting the arm moves along an arc, which simplifies and reduces the cost of the overall system. The arm can usually be tilted over a wide range, which is advantageous in job‑shop production where cutting angle and material type must often be changed.

However, this design simplicity leads to certain limitations in mechanical stability. Because the arm does not move linearly but along a circular curve during the cut, it is not possible to achieve the same downward speed of the blade across the entire width of the cut channel. The result is a variable cutting force in different parts of the cut and an increased tendency to micro‑vibrations. These vibrations, although seemingly small at first glance, can be a significant source of destructive loading for the blade, especially with harder materials or when attempting higher productivity. When cutting thin‑walled profiles this characteristic may not be critical. However, when cutting solid materials, it leads to a slowdown of the cutting process and increases demands on the operator and machine setup. This is also one reason why pivot (hinged) saws are slower in practice when cutting solid materials.

Although various types of bimetal saw blades can be used on pivot (hinged) band saws, their structural stiffness is often insufficient for the economical use of carbide (tipped) blades. Carbide blades do provide substantially higher cutting speeds, but they are significantly more sensitive to vibrations and irregularities in cutting load. For this reason, using carbide blades on pivot (hinged) band saws is technically possible but in the vast majority of cases uneconomical.

Double‑column band saws: stability, linear guidance and high productivity

Double-column band saws represent a design solution primarily focused on eliminating vibrations and maximizing accuracy. An arm guided on two parallel columns moves in a precise linear path, ideally on linear guides, with almost no play. The two‑sided support of the arm minimizes mechanical oscillation and allows even distribution of the load on the blade throughout the cut across the full width of the cutting channel.

This stability is the key factor why double-column saws can achieve many times higher cutting speeds when cutting solid materials compared with pivot (hinged) saws, even when both use standard bimetal blades. Besides the higher structural stiffness, an important factor is the ability to maintain a constant linear downward speed of the blade into the cut. As a result, the cutting force is stable, and the cut proceeds theoretically without micro‑vibrations that would otherwise damage the blade teeth or reduce blade life.

The difference in cutting speed, however, varies by material type. While the speed increase for solid cross‑sections is very pronounced (even with standard blades), differences are smaller for profile materials (especially thin‑walled profiles), often amounting to single digits or low tens of percent.

Thanks to their stiffness, double-column band saws make it feasible to use carbide blades as a standard solution. Carbide blades require maximum stability of the cutting process; on a low‑stiffness machine their teeth would be exposed to an excessive risk of damage. On double-column band saws, however, carbide blades enable a dramatic increase in productivity, especially when cutting highly alloyed steels, stainless steels and other high‑strength materials.

Cutting dynamics and the influence of vibrations

Vibrations are one of the main enemies of the saw blade. Besides negatively affecting cut quality, they cause local overloading of individual teeth. The sharp but brittle teeth of saw blades (both bimetal and carbide) have little tolerance for shocks and micro‑oscillations that arise from uneven cutting forces. For this reason, from a design perspective the entire saw is engineered to minimize vibration generation: from a massive frame through blade guidance, precise bearing supports, geometric stability of the arms to vibration damping at the vice.

A hinged design with a single pivot point is inherently more prone to vibration because it allows more degrees of freedom of movement. In contrast, a double-column design with linear guidance provides a significantly higher level of passive damping. This difference is so fundamental that it substantially affects the overall operating economy in practice - especially when using carbide blades, which are faster than bimetal blades but also more sensitive to damage.

Conclusion

Each of the band saw design concepts has clearly defined technical strengths. Pivot (hinged) band saws offer high flexibility, easy capability for miter cuts and a simple construction suitable for general workshop use. Double-column band saws provide exceptional stability, accuracy, and high productivity, particularly when cutting solid and high‑strength materials, also thanks to the effective use of carbide blades. It should be noted, however, that double-column machines are structurally significantly more complex and use more expensive technical solutions, which is reflected in their price - commonly 50–100% higher, and in some cases even more, than comparable hinged models.

Pilous offers a wide range of both pivot (hinged) and double-column band saws, and its sales specialists are ready to recommend the optimal solution with regard to the desired level of automation and the customer’s budget. Proposals for suitable accessories, such as roller conveyors precisely designed for the given type of operation, are of course part of the service. Send your inquiries and requirements to metal@pilous.cz.