Choosing a bandsaw by the saw blade – tool limits

Another aspect to consider when choosing a band saw is the size (height) of the saw blade and the availability of tooth pitches for that blade. The saw blade, as the tool of the band saw, is a very important factor when selecting a machine for cutting a specific material composition. In machine design, the blade height largely determines the subsequent size of the band saw and thus its price.

The saw blade runs over the drive wheels, is guided in the bearings into the cutting direction, and is directed into the cut by carbide guide pads. The stability of the blade in the cut is largely ensured by well-adjusted carbide guide pads. If the blade guidance in the carbide pads is too loose, the blade can very easily be undercut. How to properly eliminate this play can be found in THIS VIDEO. The higher the blade, the higher the guidance in the bearings and carbides that can be provided, and the more stable the blade is in the cut.

We illustrate this best with an example: the band saw ARG 130 K is capable of cutting through a pipe with a diameter of 130 mm. The same material can also be cut with the ARG 235 PLUS band saw, but the difference lies in the blades used. The ARG 130 K uses a blade only 13 mm high, whereas the ARG 235 PLUS uses a 27 mm high blade. The carbide guide blocks for the higher blade are more than twice as tall. In practice, this means that with equally extended guide blocks on both saws, the blade’s stiffness against twisting is many times higher on the ARG 235 PLUS with the 27 mm blade, which usually leads to better quality and higher cutting speed. The result, however, also depends to a large extent on the machine operator. For thin-walled profiles, the difference will not be as pronounced as when cutting solid or tough materials.

What about solid materials?

With solid materials, it is a bit more complicated. Renowned German manufacturers of saw blades produce blades based on many years of experience and market needs. As a band saw manufacturer, we work closely with them and adapt our machines. One of the basic rules is: the maximum recommended diameter of solid material is determined by the blade height. A simplified orientation table for common carbon steel:

| BLADE HEIGHT | DIAMETER OF SOLID MATERIAL |

| 27 mm | up to ø 150 mm |

| 34 mm | up to ø 250 mm |

| 41 mm | up to ø 400 mm |

| 54 mm | up to ø 550 mm |

| 67 mm | up to ø 690 mm |

| 80 mm | over ø 690 mm |

This does not mean, for example, that with the ARG 235 PLUS (27 mm blade) it is impossible to occasionally cut a solid material of 230 mm diameter. It means that the blade is designed for optimal use of its potential (cut quality and speed), ideally up to a diameter of 150 mm for common carbon steel. When cutting larger diameters, undercutting or a significant impact on machine performance can occur more easily. In practice, this means that larger solid materials can also be cut on the ARG 235 PLUS, but cutting conditions must be fundamentally adjusted, and one should possibly allow for a larger allowance for subsequent machining.

When selecting NC automatic machines, it is advisable to adhere to this table more strictly.

Saw blade and tooth pitch options

For a thorough selection of the saw, it is necessary to consider the available tooth pitches offered for the given blade – this reveals further machine limits.

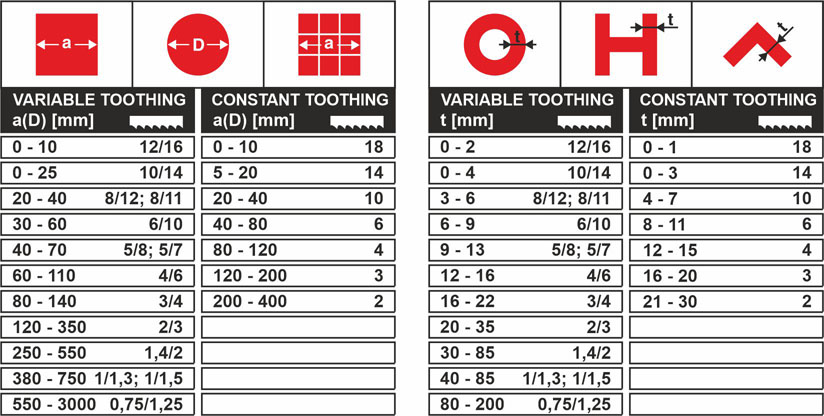

Table VARIABLE TOOTH PITCH M 42 - for materials up to tensile strength Rm 1400 N/mm²

| 0,75/1,25 | 1/1,3 | 1,4/2 | 2/3 | 3/4 | 4/6 | 5/8 | 6/10 | 8/12 | 10/14 | 12/16 | |

| 13×0,65 | ● | ● | ● | ● | |||||||

| 13×0,9 | ● | ● | ● | ||||||||

| 20×0,9 | ● | ● | ● | ● | ● | ● | ● | ||||

| 27×0,9 | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 34×1,1 | ● | ● | ● | ● | ● | ● | ● | ||||

| 41×1,3 | ● | ● | ● | ● | ● | ● | |||||

| 54×1,3 | ● | ● | ● | ● | |||||||

| 54×1,6 | ● | ● | ● | ● | ● | ● | |||||

| 67×1,6 | ● | ● | ● | ● |

Table of correct blade tooth pitch usage with respect to the material being cut

From the tooth pitch tables, for example, it follows that the 13×0.65 mm M42 blade can be supplied with a maximum coarse tooth pitch of 5/8, which corresponds to solid material up to a maximum of 70 mm. Conversely, the ARG 520 DC S.A.F. band saw with a 41×1.3 mm blade and the finest tooth 6/10 is not suitable for cutting solid materials smaller than 30 mm, nor for thin-walled tubes with a wall thinner than 6 mm.

Consider this information as a basic guide when selecting a machine. For precise recommendations, it is always necessary to take into account the specific material, its toughness, the required cut quality, and operating conditions.

Contact and consultation

Our specialists at Pilous will be happy to help you choose the most suitable band saw with regard to your production and budget. Contact the sales department: metal@pilous.cz.