Universal Sawblade

Why Not Use a Single Saw Blade for All Material Types and Profiles

Material Properties and Their Impact on Cutting

The decision to use one “UNIVERSAL” band saw blade for cutting all types of metallic materials and profiles may appear to be a practical and economical solution, but in reality, it introduces a range of technical and operational disadvantages. Each material has its own specific properties - hardness, toughness, structure, and thermal conductivity and each profile requires a different cutting approach. Ignoring these differences results not only in reduced cut quality but also in significantly shortened blade life, higher operating costs, and the risk of damage to both the machine and the workpiece.

Differences Between Soft and Hard Metals

Soft materials, such as aluminum or copper, behave completely differently during cutting compared to hard alloys such as stainless steel or tool steel. Soft metals tend to clog the teeth of the blade if the tooth pitch is not selected correctly. Harder materials, by contrast, require finer tooth pitch and more robust tooth construction, such as bimetal or carbide-tipped blades, which can withstand higher mechanical and thermal loads.

Using a “universal” blade often results either in an overly aggressive cut that deforms soft material or in inefficient, slow cutting of hard metals, which accelerates blade wear and lowers productivity. A common mistake in practice occurs when cutting aluminum with a “universal” fine-tooth bimetal blade. Aluminum tends to clog the teeth, leading to overheating and loss of cutting efficiency. In such cases, a blade with a coarser tooth pitch, providing better chip clearance, would be more suitable.

Shape and Profile of the Workpiece

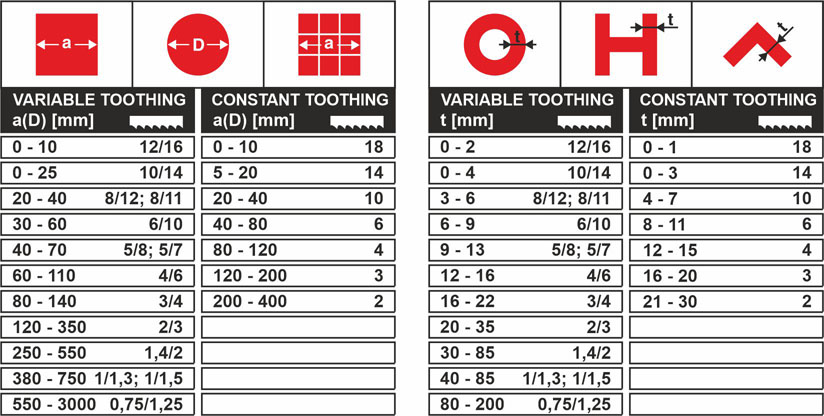

Another crucial factor is the shape and profile of the material being cut. Solid bars, blocks, or round stock require a different blade type than thin-walled profiles such as tubes, hollow sections, or angles. For thin-walled profiles, a finer tooth pitch must be used to avoid tearing, vibration, or tooth breakage. Conversely, for solid materials, a coarser tooth pitch is preferable, as it enables faster chip evacuation and more efficient cutting. A “universal blade” fails again in this regard, as it cannot optimally handle varying geometries and wall thicknesses. Tooth gullet size is critical. Fine-tooth blades clog when cutting solids, causing the blade to overheat, jump, vibrate, and cut inefficiently until teeth break. Vibrations are the greatest enemy of band saw blades. On the other hand, when cutting profiles with a coarse-pitch blade, too few teeth engage in the cut, subjecting individual teeth to extreme stress, leading to tooth breakage.

The basic rule is: at least 4 teeth, but no more than 25 teeth (optimally 10–15 teeth), must be engaged in the cut at any given time.

Thermal Load and Blade Life

The thermal load generated during cutting differs by material. For example, stainless steel has low thermal conductivity, causing the blade to heat up quickly. If the blade is not designed for such conditions, overheating occurs, resulting in loss of tooth hardness, blade deformation, or premature breakage. Selecting the correct blade with appropriate tooth geometry and body material greatly extends blade life and ensures stable performance. For these demanding applications, blades such as M51 or carbide-tipped versions are recommended.

Economic Impact of the Universal Approach

From an economic standpoint, using one blade for everything may seem cost-saving, but the opposite is true. Frequent replacements, higher blade consumption, unnecessary downtime, increased energy costs, and reduced productivity all drive operating costs up. In addition, an improperly selected blade can damage the workpiece, reducing the quality of the finished product and leading to claims or rework.

Cut Quality as a Key Factor

Cut quality is another key aspect. An unsuitable blade can cause crooked cuts, excessive burrs, profile deformation, or dimensional inaccuracies, all of which negatively affect subsequent processes such as machining, welding, or assembly. The correct blade ensures clean, straight, and precise cuts without the need for additional work, saving both time and money.

Recommendations

Using one band saw blade for all types and profiles of metallic materials is a compromise that rarely pays off. Each material and profile requires an individual approach that takes into account its physical properties, cut quality requirements, and operational efficiency. Choosing the right blade is not just a technical necessity - it is a strategic decision that influences production efficiency, customer satisfaction, and long-term business sustainability.

Practical Guidelines for Selecting a Band Saw Blade

- Consider wall thickness - as a rule, the thinner the wall, the finer the tooth pitch required. For solid materials, a coarser pitch is recommended.

- Consider material type - soft metals require blades with wider tooth pitch, while hard metals need more robust tooth construction and finer pitch.

- Use cutting fluid - particularly when cutting stainless or tool steels, cooling is essential for extending blade life. In these cases, a higher oil concentration in the coolant (typically double) is recommended.

- Regularly inspect blade condition - worn or damaged teeth reduce cut quality and may damage the machine.

- Do not believe in “universal blades” - while some blades may handle a variety of materials, it is always better to use a blade optimized for the specific application.

- Consider investing in carbide-tipped blades - for demanding applications involving hard materials, carbide blades provide significantly longer life. These blades are best suited for band saws with dual-column designs and rigid saw arm mounting - linear guiding.

Conclusion

Selecting the correct band saw blade is not just a technical requirement but a strategic decision that impacts production quality, efficiency, and operating costs. Using a single blade for all applications may seem attractive, but ultimately leads to higher costs, frequent replacements, and poor results. To achieve professional outcomes, blades must be chosen according to material type, profile, and cutting requirements.

Our specialists will gladly advise you in selecting the most suitable blade for your application. With professional support, your Pilous band saw will operate flawlessly and at maximum efficiency for many years. Contact our blade department at komarek@pilous.cz