Bi-metal M 42

Universal saw blade suitable for cutting of a wide range of materials including tool steel and stainless steel up to the hardness of 45 HRC. The teeth are made of HSS-M42 steel with cobalt content.

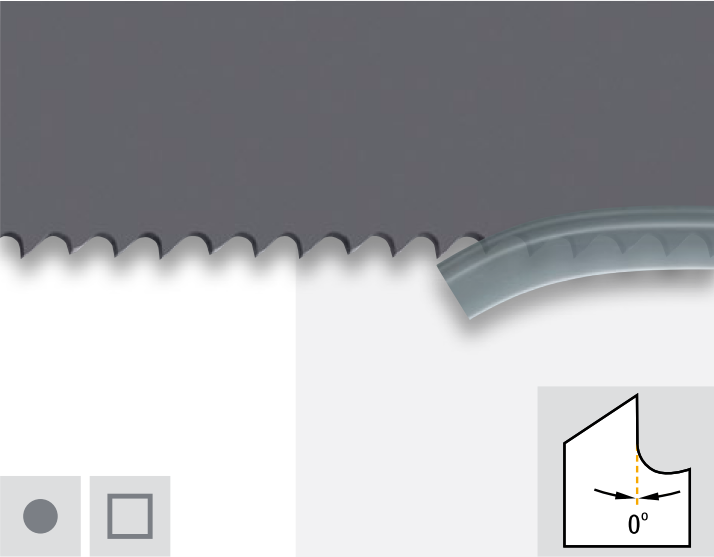

Maxtech 420 / constant toothing

Characteristics:

tooth tips made of HSS M42 1.3247 ● standard tooth with zero or slightly positive tooth face angle and standard, or corrugated setting ● excellent for cutting of materials with short chips as well as thin-walled materials ● clean and smooth cut.

Use:

- common types of steel

- up to tensile strength of approx. 1400 N/mm2

- non-ferrous metals

- material cross-section up to 1000 mm

- shape cutting on vertical machines.

| Number of teeth per inch | |||||

|---|---|---|---|---|---|

| [mm] | 4 | 6 | 10 | 14 | 18 |

| 13 x 0,65 | N | N | N | ||

| 13 x 0,9 | N | N | |||

| 20 x 0,9 | N | N | N | ||

| 27 x 0,9 | N | N | |||

N = standard tooth shape

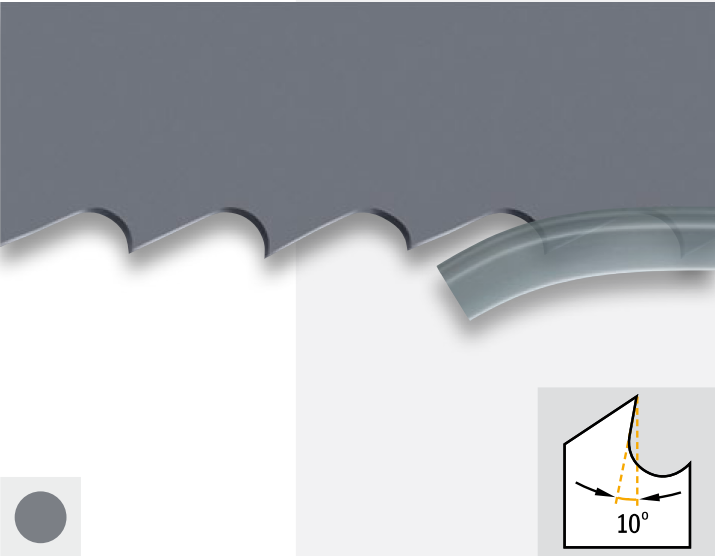

Maxtech 421 / constant toothing

Characteristics:

tooth tips made of HSS M42 1.3247 ● tooth with positive tooth face angle and standard setting easily penetrates into the material can perfectly create chip in materials with larger diameters ● cuts easily tough materials and materials with long chips ● cuts smoothly and accurately.

Use:

- common types of steel up to tensile strength of approx. 1400 N/mm2

- non-ferrous metals

- material cross-sections over 100 mm.

| Number of teeth per inch | ||||

|---|---|---|---|---|

| [mm] | 2 | 3 | 4 | 6 |

| 13 x 0,65 | H | H | ||

| 13 x 0,9 | H | H | H | |

| 20 x 0,9 | H | H | ||

| 27 x 0,9 | H | H | ||

H = hooked tooth shape

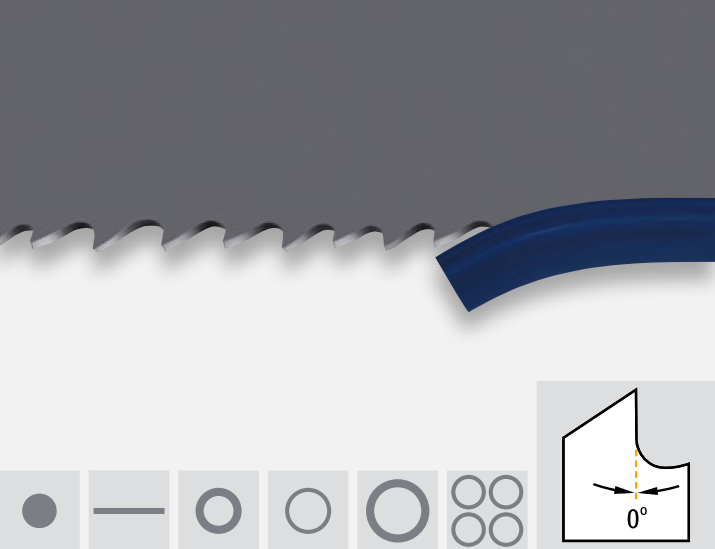

Maxtech 430 (401) / variable toothing

Characteristics:

tooth tips made of HSS M42 1.3247 ● variable tooth with tooth face angle of 0° and a special group setting ● trouble-free cutting short-chipping materials ● long service life and low cutting costs.

Use:

- common types of steel up to tensile strength of approx. 1400 N/mm2

- sections of non-ferrous metals

- cutting of individual pieces as well as bundles

- tubes and sections with little or medium wall thickness

- sheets on vertical machines.

| Number of teeth per inch | ||||||

|---|---|---|---|---|---|---|

| [mm] | 3/4 | 4/6 | 5/8 | 6/10 | 8/12 | 10/14 |

| 13 x 0,65 | V-0 | V-0 | V-0 | V-0 | ||

| 13 x 0,9 | V-0 | V-0 | V-0 | |||

| 20 x 0,9 | V-0 | V-0 | V-0 | V-0 | ||

| 27 x 0,9 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| 34 x 1,1 | V-0 | V-0 | V-0 | V-0 | V-0 | |

| 41 x 1,3 | V-0 | V-0 | V-0 | V-0 | ||

| 54 x 1,6 | V-0 | V-0 | V-0 | |||

V-0 = variable tooth with 0 angle

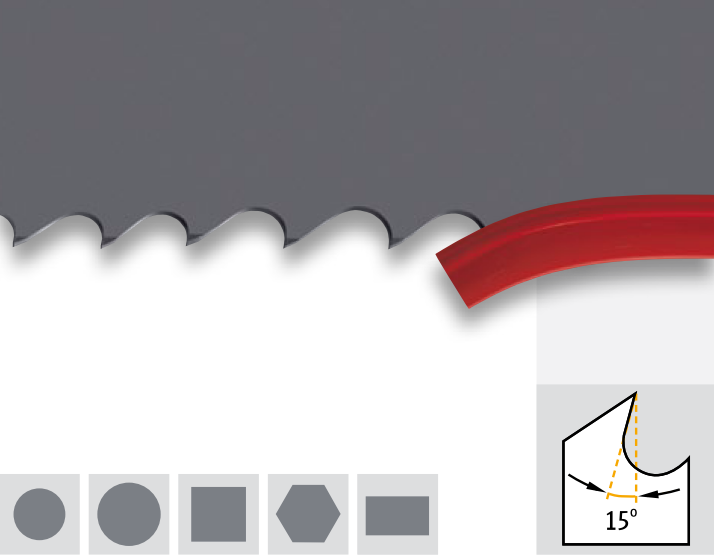

Maxtech 431 (401) / variable toothing

Characteristics:

tooth tips made of HSS M42 1.3247 ● variable tooth with positive tooth face angle and special group setting, cuts quickly and smoothly full materials as well as thick-walled sections ● long service life and low cutting costs.

Use:

- common types of steel up to tensile strength of approx. 1400 N/mm2

- sections of non-ferrous metals

- cutting of individual pieces as well as bundles

- full materials of medium or large dimensions

- thick-walled tubes.

| Number of teeth per inch | |||||

|---|---|---|---|---|---|

| [mm] | 0,75/1,25 | 1,4/2 | 2/3 | 3/4 | 4/6 |

| 20 x 0,9 | V-POS | ||||

| 27 x 0,9 | V-POS | V-POS | V-POS | ||

| 34 x 1,1 | V-POS | V-POS | V-POS | V-POS | |

| 41 x 1,3 | V-POS | V-POS | V-POS | V-POS | |

| 54 x 1,3 | V-POS | V-POS | V-POS | V-POS | |

| 54 x 1,6 | V-POS | V-POS | V-POS | ||

| 67 x 1,6 | V-POS | V-POS | |||

| 80 x 1,6 | V-POS | V-POS | |||

V-POS = variable tooth with a positive angle

Maxtech 457 (402) / variable toothing

Characteristics:

tooth tips made of HSS M42 1.3247 ● variable tooth with a new HL shape, slightly positive tooth face angle and a special setting ● prevention of pinching in the cut ● reduced vibrations and increased cutting performance ● surface quality and greater durability.

Use:

- for optimum performance on small and medium-sized cutting machines

- common types of steel up to tensile strength of approx. 1400 N/mm2

- cutting of individual pieces as well as bundles

- tubes, sections and beams with any wall thickness

- full material.

| Number of teeth per inch | ||||||

|---|---|---|---|---|---|---|

| [mm] | 2/3 | 3/4 | 4/6 | 5/7 | 8/11 | 12/16 |

| 20 x 0,9 | V-POS | V-POS | V-POS | |||

| 27 x 0,9 | V-POS | V-POS | V-POS | V-POS | V-POS | |

| 34 x 1,1 | V-POS | V-POS | V-POS | V-POS | V-POS | |

| 41 x 1,3 | V-POS | V-POS | V-POS | V-POS | V-POS | |

| 54 x 1,3 | V-POS | V-POS | ||||

| 54 x 1,6 | V-POS | V-POS | V-POS | |||

V-POS = variable tooth with a positive angle

Maxtech 434 / variable toothing

Characteristics:

tooth tips made of HSS M42 1.3247 ● specially designed variable tooth with a particularly positive tooth face angle cuts aggressively tough materials ● reduced cutting forces and easy chip formation ensure precise cutting and durability of the saw blade.

Use:

- long-chip steel materials

- stainless steel

- titanium alloys

- special bronzes

- copper alloys

- nickel-based alloys

- exotic, hard-to-divide alloys

- full material of medium dimensions.

| Number of teeth per inch | |||

|---|---|---|---|

| [mm] | 1,4/2 | 2/3 | 3/4 |

| 29 x 0,9 | V-POS | ||

| 34 x 1,1 | V-POS | V-POS | |

| 41 x 1,3 | V-POS | V-POS | |

| 54 x 1,3 | V-POS | ||

| 54 x 1,6 | V-POS | V-POS | V-POS |

V-POS = variable tooth with a positive angle