CTR 550

We confirm receipt of noncommittal demand

Demanded machine: CTR 550

Firstname:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to website

Feed into the cut and back - hand-operated

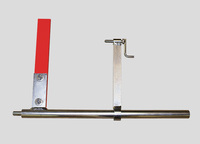

Arm height adjustment - manual

Control panel - on a mobile bridge

Log handling - manual

The smallest machine in the offer. It is designed primarily for cutting smaller volumes of lumber. Ideal solution for family farms or small sawmilling companies. Very simple hand feed into the cut and back. The control panel is placed on a mobile bridge of the sawmill arm. Thanks to that the operator has closer access to the workpiece when cutting. Height is adjusted using a hand crank with adjustable scale.

The solidly mounted drive wheel is driven via a V-belt by a professional electric motor, specially balanced against vibration. The machine's total input power of 4 kW guarantees low running costs and easy connection to the mains. Circuit breaker 16 A.

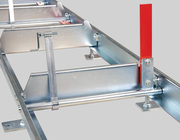

The tensioning wheel system moves in a cast iron guide, which guarantees long service life and precision adjustment even with long-term use of the machine. The arm is fitted with aluminium running wheels with precise anti-vibration balancing. The circumference of the wheel has a recessed groove in which a replaceable rubber-textile V-belt is fitted, which forms the contact surface between the wheel and the saw blade. The stability of the machine is based on solid steel travel sections, which ensure optimum guidance of the sawmill bridge. The travel sections are fitted with tilting angle bars and log clamps/cam dogs.

The CTR 550 uses standard sawmill blades 27-35 x 0.9 mm as with the fully professional models.

The CTR model series represents the latest trends in log-cutting sawmill design, with special emphasis on maximum accuracy and long service life at minimum cost. The machines are designed in an original modular way, which allows easy replacement or adjustment of all main technical nodes and their individual parts. This significantly reduces maintenance costs in the long-term use of the machine and also reduces service times, thus reducing production downtime.

All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement.

| Max. log diameter | 550 mm |

| Max. opening tetwen blade guides | 400 mm |

| Max. elevation of blade | 465 mm |

| Min. log height | 20 mm |

| Max. depth of cut | 200 mm |

| Max. log length (standard model) | 3,6 m |

| Length track section | 2,25 m |

| Min. log length | 0,9 m |

| Saw blade motor | 4 kW |

| Saw blade | 3110 x 27÷35 x 0,9 mm |

| Weight (standard model) | 280 kg |

| Weight (track section) | 54 kg |

Nomimal current of circuit breaker is minimally 20 Ampere

SPECIAL ACCESSORIES

CONSUMABLE PARTS

Machine assembly

-

Feed into the cut and back - hand-operated

Arm height adjustment - manual

Control panel - on a mobile bridge

Log handling - manualThe smallest machine in the offer. It is designed primarily for cutting smaller volumes of lumber. Ideal solution for family farms or small sawmilling companies. Very simple hand feed into the cut and back. The control panel is placed on a mobile bridge of the sawmill arm. Thanks to that the operator has closer access to the workpiece when cutting. Height is adjusted using a hand crank with adjustable scale.

The solidly mounted drive wheel is driven via a V-belt by a professional electric motor, specially balanced against vibration. The machine's total input power of 4 kW guarantees low running costs and easy connection to the mains. Circuit breaker 16 A.

The tensioning wheel system moves in a cast iron guide, which guarantees long service life and precision adjustment even with long-term use of the machine. The arm is fitted with aluminium running wheels with precise anti-vibration balancing. The circumference of the wheel has a recessed groove in which a replaceable rubber-textile V-belt is fitted, which forms the contact surface between the wheel and the saw blade. The stability of the machine is based on solid steel travel sections, which ensure optimum guidance of the sawmill bridge. The travel sections are fitted with tilting angle bars and log clamps/cam dogs.

The CTR 550 uses standard sawmill blades 27-35 x 0.9 mm as with the fully professional models.

The CTR model series represents the latest trends in log-cutting sawmill design, with special emphasis on maximum accuracy and long service life at minimum cost. The machines are designed in an original modular way, which allows easy replacement or adjustment of all main technical nodes and their individual parts. This significantly reduces maintenance costs in the long-term use of the machine and also reduces service times, thus reducing production downtime.

All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement.

-

Max. log diameter 550 mm Max. opening tetwen blade guides 400 mm Max. elevation of blade 465 mm Min. log height 20 mm Max. depth of cut 200 mm Max. log length (standard model) 3,6 m Length track section 2,25 m Min. log length 0,9 m Saw blade motor 4 kW Saw blade 3110 x 27÷35 x 0,9 mm Weight (standard model) 280 kg Weight (track section) 54 kg Nomimal current of circuit breaker is minimally 20 Ampere

-

SPECIAL ACCESSORIES

CONSUMABLE PARTS

-

Machine assembly