I have an old band saw and it undercuts, it doesn't cut straight. What to do?

Over more than 30 years of its existence, Pilous has produced thousands of various types of band saws. Owners treat their machines differently - some are hidden under piles of chips, others look as if they have just left the factory. Both groups, however, require regular maintenance. An advantage of Pilous machines is the availability of spare parts even after thirty years. In our factory, we routinely refurbish machines 25 to 30 years old. In this article, we will focus on machine adjustment and describe the factors that affect the straightness of the cut.

Machine setup

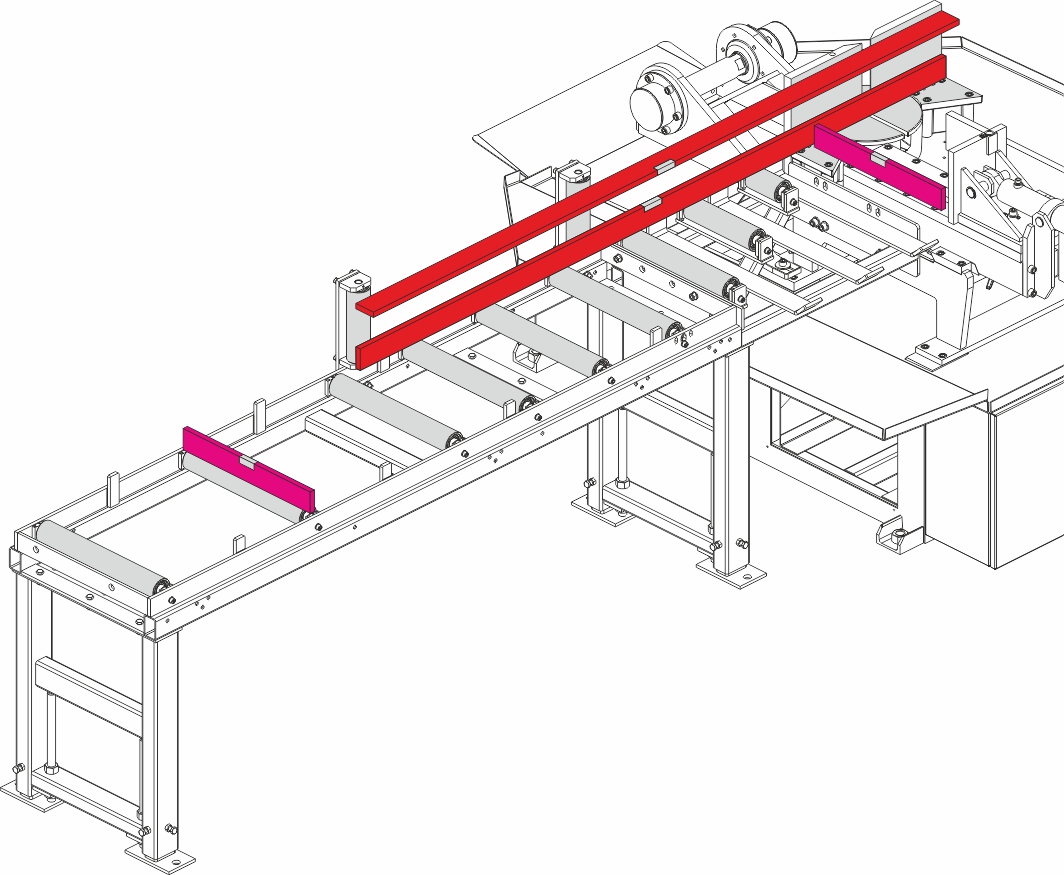

Many causes of crooked cuts stem from improper setup of the machine and conveyors. We recommend starting by checking the machine table - the place where material is placed, usually between the vice jaws. Ideally, level the machine with a spirit level (for higher accuracy, use a machinist’s level) in two mutually perpendicular planes: in the direction of material feed and in the direction of cutting.

Support the machine at the corners with plates and anchor it to the floor. Then align the conveyor with the machine using a long straightedge and a level. For each conveyor section, check all rollers to see if they touch the straightedge you place on them, and adjust their bearings if necessary. Level each section with the adjustable legs so it is flush with the machine table. Remember to level the conveyor in both mutually perpendicular axes. For longer conveyor runs a laser level is recommended. Once the machine table and conveyors are aligned, anchor the conveyors. Helpful VIDEO HERE

The basics are covered.

Material clamping

On older machines, due to play in the vice or wear of the clamping jaws, the material can be lifted when clamped, which leads to a crooked cut. Check for play in the vice and, if necessary, adjust it according to THIS VIDEO.

If the dovetail bar, vice jaws, or other parts are excessively worn, replace them. Use a square to verify that the jaws are perpendicular to the machine table.

Blade guidance - wheels

The saw blade has the greatest influence on the squareness of the cut. We will not go into which blade is suitable for which material in this article, the answer can be found in the article UNIVERSAL SAW BLADE. We will focus on blade guidance. The blade runs on the blade wheels. On older machines, the wheels are often worn, and the blade runs off the wheels. First, check the flatness of the wheel surfaces over which the blade runs. The surface must be parallel to the wheel’s axis of rotation, the wheels must not be conical. In some cases, the wheels can be repaired on a lathe, but it is better to replace them with new ones.

Blade tensioning

Correct tension of the saw blade is provided by disc springs located under the blade tensioning star. After years, these springs fatigue and need to be replaced. When replacing them, pay attention to the correct orientation of the disc springs according to the original arrangement. Use a tensiometer for precise measurement of blade tension. Do not over-tension the saw blade, tension it only according to the operating manual or the recommendations of service technicians. Excessive over-tensioning can even deform the machine arm and lead to crooked cuts. During long periods of non-use, it is advisable to loosen the saw blade.

Blade guidance in guide blocks

The saw blade is guided on the blade wheels and then redirected into the cutting position by bearings in the guide blocks. Check that all bearings in the guide blocks rotate properly.

Precise guidance and retention of the blade in the cut are ensured by carbide guide plates. These plates wear, so regularly check their clearance. The blade should run between them without play, but must not be clamped. If the blade has play, it will deflect sideways under load, and the cut will be crooked. You can easily detect play in the blocks when changing the saw blade. Take an old section of the saw blade, insert it into the guide blocks, and wobble it from side to side. Probably the most difficult task is adjusting the guide blocks. It is advisable to make a fixture that helps adjust the blocks comfortably and accurately. WITH THIS VIDEO, it's a breeze.

Correct position of the saw blade on the wheels

The saw blade must not run off the blade wheels nor ride onto the wheel flange. A minimal clearance of about 1-2 mm from the wheel flange is appropriate. Monitor this clearance during cutting, there is a spy hole in the arm for this purpose. On older machines, this spy hole can be drilled into the arm. The clearance is set with the blade loosened by tilting the tensioning wheel according to the operating manual. A short VIDEO helps here as well.

Arm coupling

Finally, perform a last test that will determine whether the problem with the crooked cut is in the machine or in the saw blade and cutting conditions. Due to the complexity of the arm coupling, you will probably not be able to repair this problem yourself. The good news is that this problem occurs rarely, more often, the fault lies with the saw blade and the cutting conditions.

The test is best performed by two people. Procedure: Raise the machine arm to the upper position. Place a long square perpendicular to the saw blade and rest it on the machine table. Use feeler gauges, for example, 0.5 mm, and insert a gauge between the square and the tooth of the saw blade that is bent toward the square. The square must be supported over its entire face on the table, and the gauge should slide freely between the square and the saw blade. This sets the clearance in the upper position of the blade. Now lower the arm to the lower position and measure with the gauge the distance of the tooth from the square. Ideally, the gap is the same at the top and bottom. On an older machine, a difference up to 0.5 mm is acceptable, or according to your requirements. This measures the theoretical undercut over the entire diameter, i.e., over the entire stroke of the blade. If the undercut on the workpiece is greater than this difference, the problem is in the saw blade, cutting conditions, etc., not in the machine.

Conclusion

In this article, we have summarized the most common causes and circumstances leading to crooked cuts and offered procedures for their elimination. Pilous service technicians are available to assist you with technical problems. If you need a specific spare part, provide the machine type, the serial number from the nameplate, and the part specification. For older machines where documentation is missing, usually sending a photograph of the required part is sufficient. If you do not feel confident performing service tasks yourself, we recommend sending the machine to our production plant for service work.

Contact: servis@pilous.cz