ARG 300 CF-NC automat

We confirm receipt of noncommittal demand

Demanded machine: ARG 300 CF-NC automat

Company:

Kontaktní osoba:

VAT:

Adresa:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to website

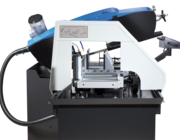

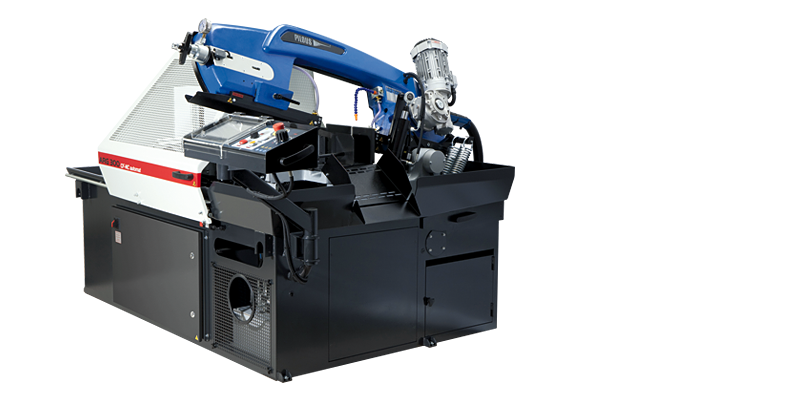

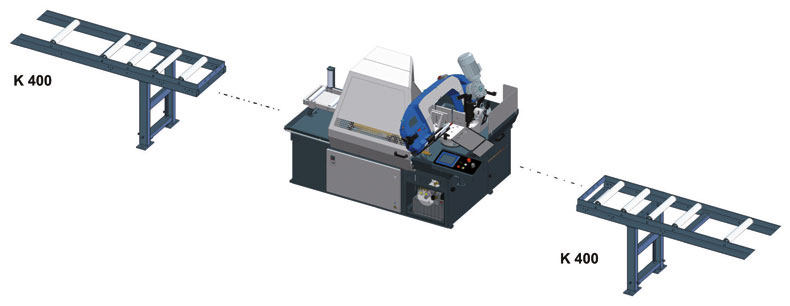

The upgraded version of the legendary ARG 300 CF - NC with a completely new saw blade arm. The most up to date concept of the cast iron arm creates a closed section that is hollow along its full length at all load-carrying points. This guarantees outstanding stiffness of the entire system, maximum accuracy during cutting and a long service life of the saw blade. A new unique design.

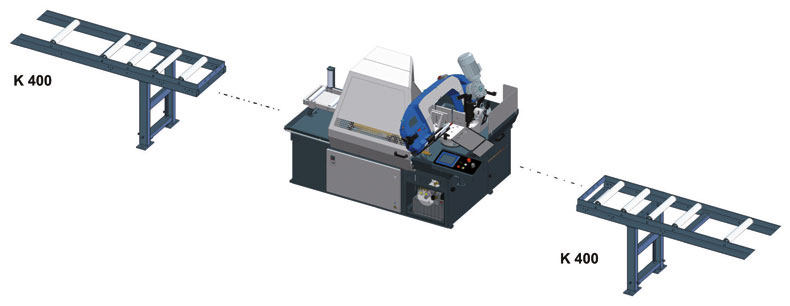

Fully automated CNC band saw is generally suitable for cutting big series in the heaviest and non-stop operating plants, and also for cutting heavy workpieces of larger cross-sections. The machine is equipped with a workpiece feed by industrial servomotor with a new control system. The servomotor and ball screw ensure high speed and maximum accuracy of workpiece feed, even in multiple feed when cutting long pieces. Options of setting three feed rates – 27, 42 or 50 mm/second acording to weight and length of the workpiece to be cut. Maximum length of a single feed is 500 mm.

Central control panel with a big colour touch screen (7.5”) ensures simple intuitive control of all features of the machine. The control unit allows for programming of up to 60 programmes for quick setting of the feed length in repetitive production. Each programme can be annotated, e.g. by the drawing number. Possibility of programming and cutting of different number of pieces of different sizes without the need for further operation of the machine.

The machine can be controlled in fully automatic, semi-automatic or manual mode. In manual mode all functions of the machine are controlled separately. Workpiece clamping and arm feed to and away from the cut in the desired position according to section of the workpiece are controlled by hydraulics. The so-called “floating” design of the feed vice ensures accurate feeding of uneven and crude workpieces. Regulation of pressure of the feeding and fixed vice is included in the standard equipment.

Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw blade speed by a frequency converter in the range between 15 and 90 m/min, which significantly contributes to cutting accuracy and service life of saw blades. Maximum accuracy of workpiece feeding is based on a very robust construction of the machine with all the main parts made of grey cast iron and massive framework of the feeding system.

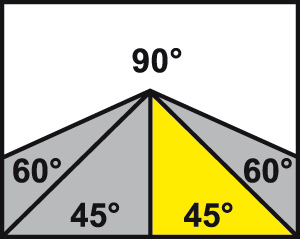

Large base and overall massive framework guarantee exceptional stability of the machine even when cutting heavy workpieces. The base is equipped with a large removable chips container and allows for installation of an optional worm chips container. Industrial band 27 x 0.9 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel. Continuous manual setting of the cutting angle within 90°–45°. The material can be cut by angular cutting or in automatic mode as well.

- Modern concept of the band saw arm allows for large cutting ranges in upright and angular cuts.

- All of electrical wiring and coolant distribution are concealed in hollow parts of the arm which means they are protected from damage.

- The new concept of the arm also brings a great simplification when changing the saw band or when cleaning the inside of the arm. You just need to open the hinged back cover of the arm and it will stay locked in the upper position.

- Large diameter blade wheels and precise three-side hardened steel blade guides ensure long service life of the blade and cutting accuracy.

- Overdesign of blade wheel bearings, tensioning wheel system and all rotary parts ensure long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with worm gearbox.

- The machine is connected to a complete cooling system with high-performance pump and possibility of regulating the flow on both guiding heads independently and on an additional adjustable outlet. Coolant tank with a high-performance pump are placed in the base of the machine.

- The machine checks correct tension or breakage of the saw blade. If the saw blade breaks the machine automatically switches off.

- Easy intuitive controls by ergonomically placed controls on the rotary central control panel.

| 90° | +45° | |

|

300 | 240 |

|

285 | 220 |

|

305 x 290 | 235 x 130 |

| Main motor | 400 V, 50 Hz, 2,2 kW |

| Pump motor | 400 V, 50 Hz, 0,05 kW |

| Hydraulic motor unit | 400 V, 50 Hz, 0,55 kW |

| Servo motor of the feed | 1,3 / 2 kW |

| Feed rate of material | 1,6 / 2,5 / 3 m/min. |

| Saw blade speed | 15-90 m/min. |

| Working height of vice | 850 mm |

| Hydraulic system oil | cca 26 l (ISO 6743/4-HM, DIN 51 524 part 2-HLP) |

| Coolant tank | cca 35 l |

| Machine dimensions | Dimension drawing |

| Machine weight | 1020 kg |

-

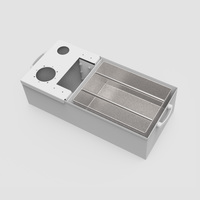

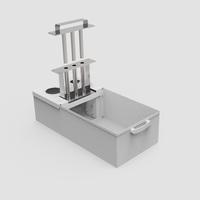

Magnetic chip separator

For particularly fine chips that have passed through the sieves in the saw, a highly efficient magnetic separator is used. It saves time for cleaning and disassembling the cooling path and extends the service life of the cooling emulsion. This device is easily removable and easy to clean outside the machine by simply pulling the magnetic bars out of the housing.

The sawblade replacement

-

The upgraded version of the legendary ARG 300 CF - NC with a completely new saw blade arm. The most up to date concept of the cast iron arm creates a closed section that is hollow along its full length at all load-carrying points. This guarantees outstanding stiffness of the entire system, maximum accuracy during cutting and a long service life of the saw blade. A new unique design.

Fully automated CNC band saw is generally suitable for cutting big series in the heaviest and non-stop operating plants, and also for cutting heavy workpieces of larger cross-sections. The machine is equipped with a workpiece feed by industrial servomotor with a new control system. The servomotor and ball screw ensure high speed and maximum accuracy of workpiece feed, even in multiple feed when cutting long pieces. Options of setting three feed rates – 27, 42 or 50 mm/second acording to weight and length of the workpiece to be cut. Maximum length of a single feed is 500 mm.

Central control panel with a big colour touch screen (7.5”) ensures simple intuitive control of all features of the machine. The control unit allows for programming of up to 60 programmes for quick setting of the feed length in repetitive production. Each programme can be annotated, e.g. by the drawing number. Possibility of programming and cutting of different number of pieces of different sizes without the need for further operation of the machine.

The machine can be controlled in fully automatic, semi-automatic or manual mode. In manual mode all functions of the machine are controlled separately. Workpiece clamping and arm feed to and away from the cut in the desired position according to section of the workpiece are controlled by hydraulics. The so-called “floating” design of the feed vice ensures accurate feeding of uneven and crude workpieces. Regulation of pressure of the feeding and fixed vice is included in the standard equipment.

Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw blade speed by a frequency converter in the range between 15 and 90 m/min, which significantly contributes to cutting accuracy and service life of saw blades. Maximum accuracy of workpiece feeding is based on a very robust construction of the machine with all the main parts made of grey cast iron and massive framework of the feeding system.

Large base and overall massive framework guarantee exceptional stability of the machine even when cutting heavy workpieces. The base is equipped with a large removable chips container and allows for installation of an optional worm chips container. Industrial band 27 x 0.9 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel. Continuous manual setting of the cutting angle within 90°–45°. The material can be cut by angular cutting or in automatic mode as well.

- Modern concept of the band saw arm allows for large cutting ranges in upright and angular cuts.

- All of electrical wiring and coolant distribution are concealed in hollow parts of the arm which means they are protected from damage.

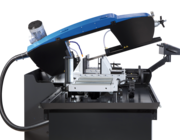

- The new concept of the arm also brings a great simplification when changing the saw band or when cleaning the inside of the arm. You just need to open the hinged back cover of the arm and it will stay locked in the upper position.

- Large diameter blade wheels and precise three-side hardened steel blade guides ensure long service life of the blade and cutting accuracy.

- Overdesign of blade wheel bearings, tensioning wheel system and all rotary parts ensure long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with worm gearbox.

- The machine is connected to a complete cooling system with high-performance pump and possibility of regulating the flow on both guiding heads independently and on an additional adjustable outlet. Coolant tank with a high-performance pump are placed in the base of the machine.

- The machine checks correct tension or breakage of the saw blade. If the saw blade breaks the machine automatically switches off.

- Easy intuitive controls by ergonomically placed controls on the rotary central control panel.

-

90° +45°

300 240

285 220

305 x 290 235 x 130 Main motor 400 V, 50 Hz, 2,2 kW Pump motor 400 V, 50 Hz, 0,05 kW Hydraulic motor unit 400 V, 50 Hz, 0,55 kW Servo motor of the feed 1,3 / 2 kW Feed rate of material 1,6 / 2,5 / 3 m/min. Saw blade speed 15-90 m/min. Working height of vice 850 mm Hydraulic system oil cca 26 l (ISO 6743/4-HM, DIN 51 524 part 2-HLP) Coolant tank cca 35 l Machine dimensions Dimension drawing Machine weight 1020 kg -

-

-

Magnetic chip separator

For particularly fine chips that have passed through the sieves in the saw, a highly efficient magnetic separator is used. It saves time for cleaning and disassembling the cooling path and extends the service life of the cooling emulsion. This device is easily removable and easy to clean outside the machine by simply pulling the magnetic bars out of the housing.

-

The sawblade replacement