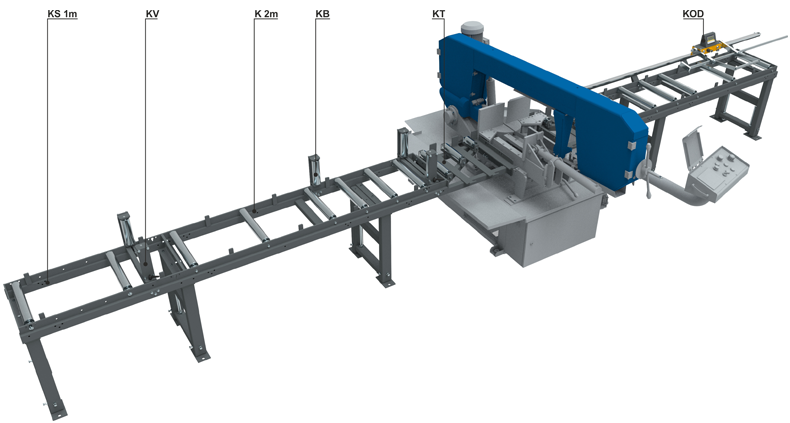

K System

Heavy roller conveyors

- Exceptionally solid and stable welded construction consisting of full sections and fitted with thick-walled lathe-manufactured steel rollers.

- The greater the width of the conveyor, the bigger and tougher the overall construction, and the larger the diameter of the rollers as well as the shafts. Roller shafts are stored in adjustable steel sleeves with bearings.

- The individual modules, 1 or 2 m long, are mutually connectable and enable for adjustment of the optimal conveyor length.

- The massive pull-out system allows for adjustable leg height in the range of 760 mm to 960 mm.

- Wide range of accessories and connection components.

| roller width | number of legs | number of rollers | roller diameter | total length [mm] | load-carrying capacity [kg/1m] |

|

|---|---|---|---|---|---|---|

| K 400 / 2m | 400 | 2 | 6 | 58 | 2000 | 500 |

| K 520 / 2m | 520 | 2 | 6 | 58 | 2000 | 600 |

| K 650 / 2m | 650 | 2 | 6 | 68 | 2000 | 1000 |

| K 750 / 2m | 750 | 2 | 6 | 74 | 2000 | 1600 |

| K 400 / 1m | 400 | 1 | 3 | 58 | 1000 | 500 |

| K 520 / 1m | 520 | 1 | 3 | 58 | 1000 | 600 |

| K 650 / 1m | 650 | 2 | 3 | 68 | 1000 | 1000 |

| K 750 / 1m | 750 | 2 | 3 | 74 | 1000 | 1600 |

KS – Extension to K conveyor

- Module length 2 m.

- The same frame is fitted with fewer rollers.

- The conveyor KS 400 and 520 are equipped with one leg, the conveyor KS 650 and 750 are for the maximum load-carrying capacity equipped with two legs.

| roller width | number of legs | number of rollers | roller diameter | total length [mm] | load-carrying capacity [kg/1m] |

|

|---|---|---|---|---|---|---|

| KS 400 / 2m | 400 | 1 | 4 | 58 | 2000 | 500 |

| KS 520 / 2m | 520 | 1 | 4 | 58 | 2000 | 600 |

| KS 650 / 2m | 650 | 2 | 4 | 68 | 2000 | 1000 |

| KS 750 / 2m | 750 | 2 | 4 | 74 | 2000 | 1600 |

| KS 400 / 1m | 400 | 1 | 2 | 58 | 1000 | 500 |

| KS 520 / 1m | 520 | 1 | 2 | 58 | 1000 | 600 |

| KS 650 / 1m | 650 | 2 | 2 | 68 | 1000 | 1000 |

| KS 750 / 1m | 750 | 2 | 2 | 74 | 1000 | 1600 |

Accessories for the K conveyors

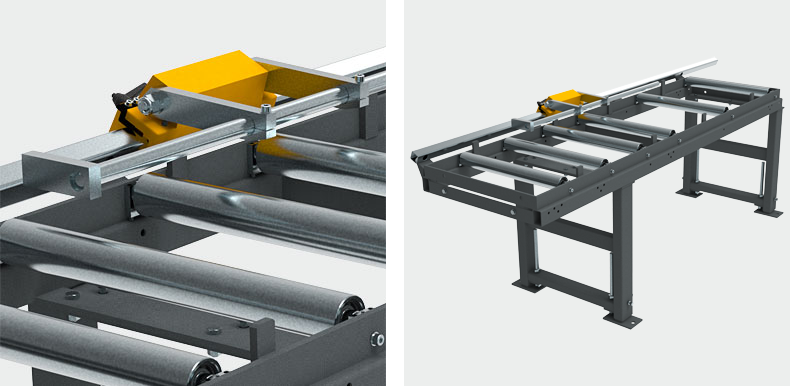

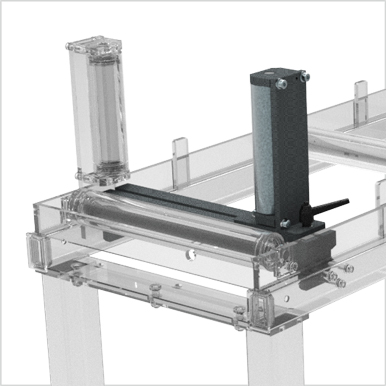

KO – Manual measuring device

- A simple and effective measuring of the required material length.

- This massive system with a robust cast iron housing of the slide stop moves on precise steel guiding and ensures great accuracy of the setting and a long service life.

- You can set the required length manually on an analogue (millimeter) scale.

- The system of movable side stop is retractable in order to prevent gripping of the material and consequent damage to the saw band.

- Can be installed on all types of K conveyors. It is manufactured in two sizes for the roller width 400, 520 mm and for the width 650 and 750 mm.

| measured length [mm] | total length [mm] | |

|---|---|---|

| KO 400, 520, 650, 750 / 2m | 2000 | 2400 |

| KO 400, 520, 650, 750 / 3m | 3000 | 3400 |

| KO 400, 520, 650, 750 / 4m | 4000 | 4400 |

| KO 400, 520, 650, 750 / 5m | 5000 | 5400 |

| KO 400, 520, 650, 750 / 6m | 6000 | 6400 |

(includes the slide stop system, feed system and an analogue scale of the appropriate length, not the conveyor itself)

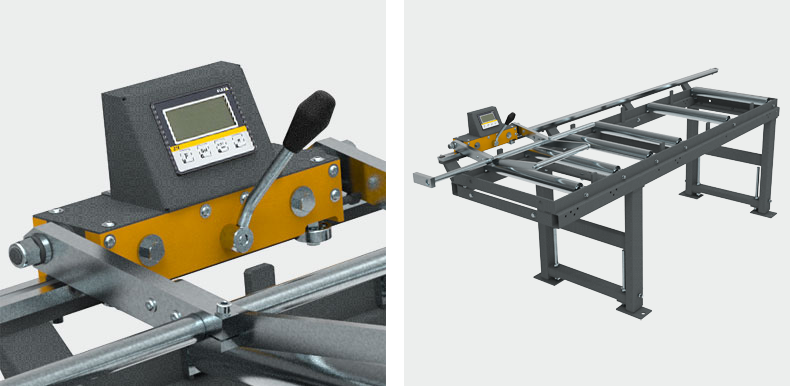

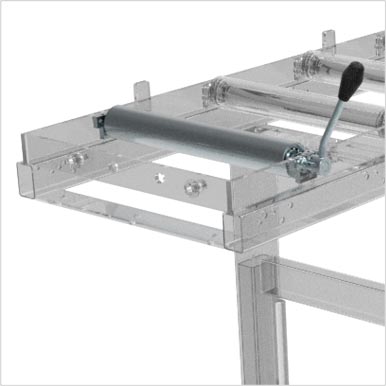

KOD – Digital measuring device

- Ensures precise and simple setting of the required length as well as display of the position on the digital display with the accuracy of 0.1 mm.

- This massive system with a robust cast iron housing of the slide stop moves on precise steel guiding and ensures great accuracy of the setting and a long service life.

- The required length is set manually and arrested. The system is fed by batteries with a long service life.

- Exceptionally stable system of movable slide stop is retractable in order to prevent gripping of the material and consequent damage to the saw band.

- Can be installed on all types of K conveyors. It is manufactured in two sizes for the roller width 400, 520 mm and for the width of 650 and 750 mm.

| measured length [mm] | total length [mm] | |

|---|---|---|

| KOD 400, 520, 650, 750 / 2m | 2000 | 2400 |

| KOD 400, 520, 650, 750 / 3m | 3000 | 3400 |

| KOD 400, 520, 650, 750 / 4m | 4000 | 4400 |

| KOD 400, 520, 650, 750 / 5m | 5000 | 5400 |

| KOD 400, 520, 650, 750 / 6m | 6000 | 6400 |

(includes the slide stop system with a digital measuring device, the feed system and a magnetic tape of the appropriate length, not the conveyor itself)

KP - Conveyor with drive powered rollers

- Motor-driven rollers enable for an easy and precise feed of heavy material.

- Smooth speed adjustment by a frequency converter allows for a smooth start and accurate landing of the material fed.

- Portable control unit allows for optimum position of the operator during precise feeding into the desired length.

- Extremely stable construction as in all K system conveyors.

- The conveyors are fitted with thick-walled lathe-manufactured steel rollers 520 or 750 mm wide with corresponding diameters.

- Roller shafts are stored in adjustable steel sleeves with bearings. The massive pull-out system allows for adjustable leg height in the range of 760 mm to 960 mm.

- Individual modules in the length of 2 m are mutually connectable. To achieve maximum stability, the 2 m conveyor is equipped with two legs.

| roller width | number of legs | number of rollers | roller diameter | total length [mm] | load-carrying capacity [kg/1m] |

motor [kW] | feed speed [m/s] | |

|---|---|---|---|---|---|---|---|---|

| KP 520 / 2m | 520 | 2 | 6 | 58 | 2000 | 600 | 0,37 | 0 - 0,3 |

| KP 750 / 2m | 750 | 2 | 6 | 74 | 2000 | 1600 | 0,37 | 0 - 0,3 |

KPS – Extension to KP conveyor

- Module length 2 m.

- The same frame is fitted with fewer rollers.

- The conveyor KPS 520 is equipped with one leg, the conveyor KPS 750 is for the maximum load-carrying capacity equipped with two legs.

- The conveyors are fitted with a chain feed system that is connected to the basic KP conveyor.

| roller width | number of legs | number of rollers | roller diameter | total length [mm] | load-carrying capacity [kg/1m] |

|

|---|---|---|---|---|---|---|

| KPS 520 / 2m | 520 | 1 | 4 | 58 | 2000 | 600 |

| KPS 750 / 2m | 750 | 2 | 4 | 74 | 2000 | 1600 |

Accessories for the conveyors of the K System

|

KB –vertical idle rollersEnable precise guiding of the material into the vice and prevent the material from falling off of the conveyor. |

|

KV – Console with a sliding vertical idle rollerAn indispensable help when cutting material in bundles. Only for conveyors in KB version with vertical idle rollers. |

|

KN – Additional conveyor leg |

|

KZ – hoist rollerA manual, eccentric system installed on the roller allows for hoisting of the material above the loading surface of the machine and thus its easier feed. |

|

KT – intermediate piece for connecting of the conveyors to the individual machinesOnly for ARG 380, 400, 500 plus S.A.F. |

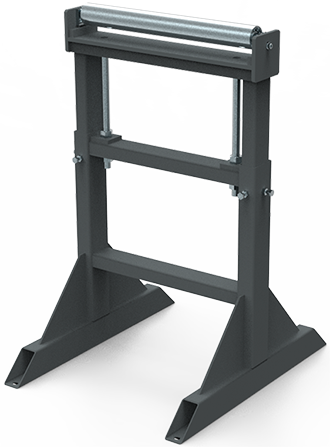

KR – Height-adjustable leg with roller

- The massive and stable welded construction is fitted with thick-walled lathe-manufactured steel roller.

- Adjus adjustable leg height ranging from 760 mm to 960 mm.

| roller width | load-carrying capacity [kg/1m] | |

|---|---|---|

| KR 520 | 520 | 500 |

| KR 750 | 750 | 600 |

KRT – Height adjustable leg with an eccentric roller

- Eccentrically stored roller allows for simple manual lift of the material onto the loading area of the vice and for its smooth movement as well.

- The roller height is adjustable in the range from 760 mm to 960 mm.

| roller width | load-carrying capacity [kg/1m] | |

|---|---|---|

| KRT 520 | 520 | 500 |

| KRT 750 | 750 | 600 |