MNY Manipulator

We confirm receipt of noncommittal demand

Demanded machine: MNY Manipulator

Company:

Kontaktní osoba:

VAT:

Adresa:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to website

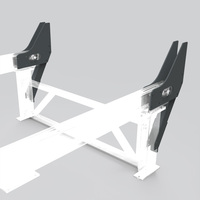

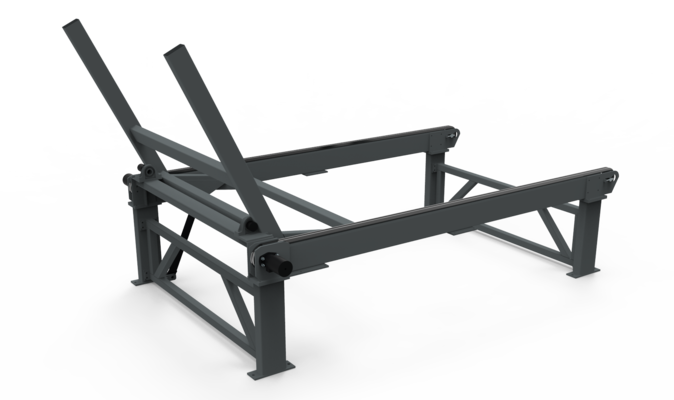

The tilting log manipulator allows fast, convenient and especially safe loading of round logs with a maximum length of 9 m onto the machine bed. By incorporating into the XMK handling line, it significantly increases the productivity of the entire operation. It is capable of handling logs with a total weight of up to 10 000 kg. The horizontal movement of the logs is carried out by means of chains that are independently controlled by hydraulic motors. The tilting angle of the arms makes it easier to load even knotted logs. The loader can be easily controlled from a separate control panel by pressing the buttons (see accessories). The control of individual components of the line can be combined into a larger control panel according to the customer’s requirements. For safety reasons, we recommend fitting the end of the loader with ZAK stops (see accessories). The log deck can be extended by a three-meter extension section with separate hydraulic motors (see accessories). If required, the unit can be supplemented with additional loading arms. Depending on preferences, this unit needs to be retrofitted with a support that defines the lower position (see accessories). To increase the load capacity and rigidity of the manipulator, order an additional support of the deck (see accessories). The manipulator does not have its own hydraulic unit for controlling the horizontal chains of the deck and tilting of the loader. It is necessary to reorder or connect to another unit of the XMK line.

SPECIAL ACCESSORIES

-

The tilting log manipulator allows fast, convenient and especially safe loading of round logs with a maximum length of 9 m onto the machine bed. By incorporating into the XMK handling line, it significantly increases the productivity of the entire operation. It is capable of handling logs with a total weight of up to 10 000 kg. The horizontal movement of the logs is carried out by means of chains that are independently controlled by hydraulic motors. The tilting angle of the arms makes it easier to load even knotted logs. The loader can be easily controlled from a separate control panel by pressing the buttons (see accessories). The control of individual components of the line can be combined into a larger control panel according to the customer’s requirements. For safety reasons, we recommend fitting the end of the loader with ZAK stops (see accessories). The log deck can be extended by a three-meter extension section with separate hydraulic motors (see accessories). If required, the unit can be supplemented with additional loading arms. Depending on preferences, this unit needs to be retrofitted with a support that defines the lower position (see accessories). To increase the load capacity and rigidity of the manipulator, order an additional support of the deck (see accessories). The manipulator does not have its own hydraulic unit for controlling the horizontal chains of the deck and tilting of the loader. It is necessary to reorder or connect to another unit of the XMK line.

-

SPECIAL ACCESSORIES