KPM

We confirm receipt of noncommittal demand

Demanded machine: KPM

Company:

Kontaktní osoba:

VAT:

Adresa:

Phone:

E-mail:

Your inquiry:

Destination country:

We will contact you as soon as possible using given contact details.

Back to website

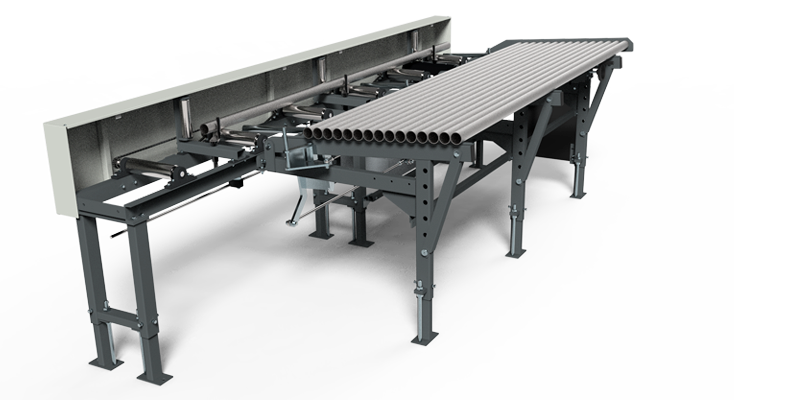

Automated material loader KPM ensures fully automated material feeding. The loading section (where the material is placed using a crane or a forklift) is tiltable and allows stacking material of circular shapes such as pipes or solid bars, as well as rectangular profiles, such as U‑profiles, flat bars, etc.

The loader is designed as an expandable, fully integrable component of the band saw and is controlled by a powerful PLC system and Pilous‑developed PilOS operating software from the bandsaw itself, which ensures communication and synchronization of all movements.

After loading the material onto the handling part of the device, individual pieces are automatically fed into the band saw using hydraulic cylinders connected to a dedicated hydraulic unit. The loader always conveys a single piece of material onto an electrically driven roller conveyor. Once placed on the conveyor, mechanical seating and pressing onto support rollers takes place, ensuring an accurate position before the feed vice.

The roller conveyor is then started smoothly using a frequency converter, which conveys the material precisely into the jaws of the feed vice. After the material is detected, the system automatically clamps it and precisely positions it into the main vice using a PMG sensor and continues the cutting cycle smoothly according to the program set by the operator. During the material advance, the speed of the roller conveyor is fully synchronized with the movement of the feed vice to prevent unwanted slipping of the material on the rollers and its damage. The entire process runs completely automatically without the need for operator intervention.

The KPM loader represents an efficient and reliable extension for the Master series band saws, significantly increasing the level of automation, productivity, time efficiency, and safety during material cutting.

| Loader 3 m | Loader 6 m | |

| Maximum material length | 4 m | 7 m |

| Minimum material length | 2 m | 2 m |

| Number of crossbars | 3 | 5 |

| Total weight | 650 Kg | 900 Kg |

| Machine dimensions | Dimensional drawing | Dimensional drawing |

| Static load per crossbar | 800 kg | 800 kg |

| Loader incline angle | 2°, 7°, 12°, 17°, 22°, 27° | 2°, 7°, 12°, 17°, 22°, 27° |

| Power consumption | 1,1 kW | 1,1 kW |

| Minimum conveyed diameter | 10 mm | 10 mm |

| Maximum conveyed diameter | 160 mm | 160 mm |

| Material height above floor | 772 - 1022 mm | 772 - 1022 mm |

-

Automated material loader KPM ensures fully automated material feeding. The loading section (where the material is placed using a crane or a forklift) is tiltable and allows stacking material of circular shapes such as pipes or solid bars, as well as rectangular profiles, such as U‑profiles, flat bars, etc.

The loader is designed as an expandable, fully integrable component of the band saw and is controlled by a powerful PLC system and Pilous‑developed PilOS operating software from the bandsaw itself, which ensures communication and synchronization of all movements.

After loading the material onto the handling part of the device, individual pieces are automatically fed into the band saw using hydraulic cylinders connected to a dedicated hydraulic unit. The loader always conveys a single piece of material onto an electrically driven roller conveyor. Once placed on the conveyor, mechanical seating and pressing onto support rollers takes place, ensuring an accurate position before the feed vice.

The roller conveyor is then started smoothly using a frequency converter, which conveys the material precisely into the jaws of the feed vice. After the material is detected, the system automatically clamps it and precisely positions it into the main vice using a PMG sensor and continues the cutting cycle smoothly according to the program set by the operator. During the material advance, the speed of the roller conveyor is fully synchronized with the movement of the feed vice to prevent unwanted slipping of the material on the rollers and its damage. The entire process runs completely automatically without the need for operator intervention.

The KPM loader represents an efficient and reliable extension for the Master series band saws, significantly increasing the level of automation, productivity, time efficiency, and safety during material cutting.

-

Loader 3 m Loader 6 m Maximum material length 4 m 7 m Minimum material length 2 m 2 m Number of crossbars 3 5 Total weight 650 Kg 900 Kg Machine dimensions Dimensional drawing Dimensional drawing Static load per crossbar 800 kg 800 kg Loader incline angle 2°, 7°, 12°, 17°, 22°, 27° 2°, 7°, 12°, 17°, 22°, 27° Power consumption 1,1 kW 1,1 kW Minimum conveyed diameter 10 mm 10 mm Maximum conveyed diameter 160 mm 160 mm Material height above floor 772 - 1022 mm 772 - 1022 mm